Plastic food containers are mainly or partly made out of plastic. Plastic food containers come in various shapes and sizes, either reusable or single-use. The best examples of plastic food containers are plastic cups, plastic bottles, plastic bags, foam food containers, and Tupperware®. Read More…

As a leader in the plastic container & plastic food container industry, Rahway Steel Drum Company supplies plastic storage containers, plastic shipping containers & more, to be used for regulated & non-regulated liquid & solid packaging. Choose from our many sizes from 1 quart to 330 gallons. For 60 years we have been a plastic container distributor of lightweight, space saving, bulk containers.

Jakacki Bag & Barrel, family owned and operated, is a plastic container manufacturer. Their products include pails, pallets, gaylords, drums and so much more.

Container Distributors offers a solution for all of your plastic container needs, including all sizes of new and reconditioned plastic containers, as well as steel and fibre drums. We also carry a wide range of cubic yard boxes and IBC/totes.

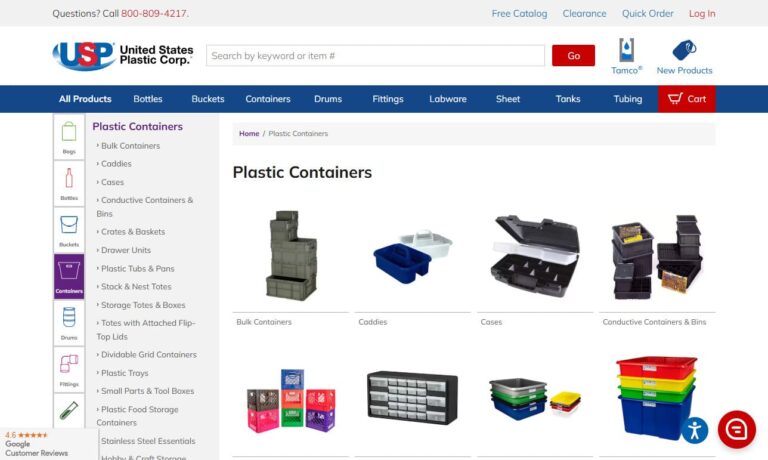

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

At BayTec Service, we specialize in providing high-quality plastic containers designed to meet the diverse needs of industries ranging from chemical processing to food storage and industrial manufacturing. We take pride in offering an extensive selection of durable, versatile containers that deliver long-term performance in demanding environments.

For the past 30 years, Western Industries has been manufacturing plastic containers for a variety of industries, and fulfilling the needs for businesses large and small. At our 350,000 square-foot manufacturing campus, we have the technology and the expertise to manufacture plastic containers of all shapes and sizes, defect-free.

More Plastic Food Container Manufacturers

Types of Plastics Used as Food Containers

Polyethylene Terephthalate (PET)

Polyethylene terephthalate, also known as PET, is a ubiquitous type of plastic used to store soft drinks, and it is used to make single-use water bottles, food-grade containers, and bakery trays. PET is not affected by food contact, which is why it is ideal for food storage.

Crystallizable Polyethylene Terephthalate (CPET)

CPET has gone through a process that allows it to resist cracking when it experiences low temperatures, which is a setback for average PET plastic containers. CPET is highly flexible and can endure higher temperatures hence why CPET produces plastic food trays that are used with conventional ovens, oven-proof plastic wraps, microwavable dinners, and storage containers. CPET plastic containers are used for packaging or storing ready-to-eat meals.

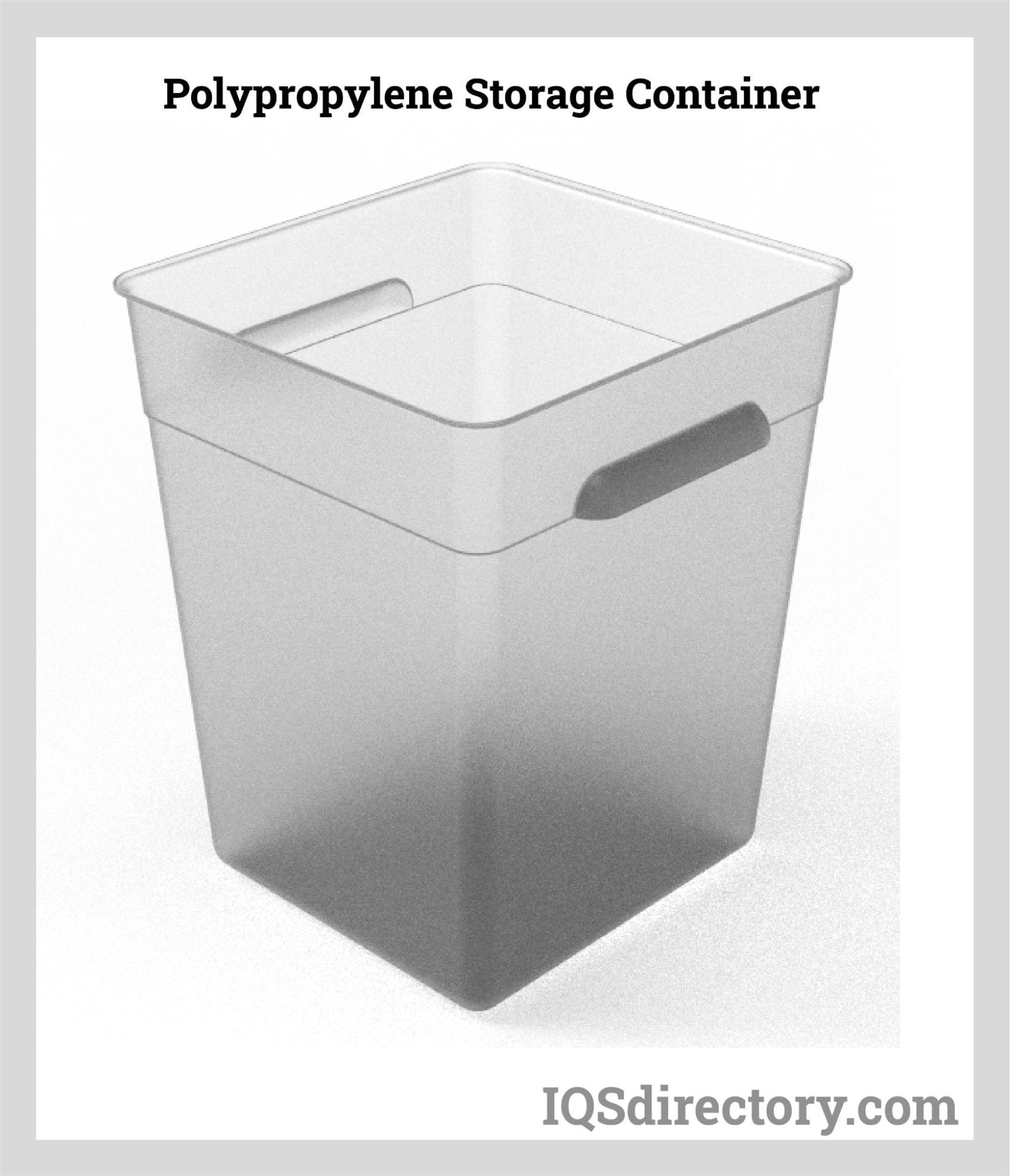

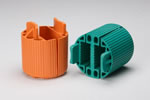

Polypropylene

Polypropylene is food-safe plastic used during production processes that require a lot of heat. Polypropylene can be found in products used as prescription bottles or garden tools. It is a stiff kind of plastic, but it is not brittle as compared to the other kinds of food container plastics. Food items that use polypropylene for storage are yogurts, cream cheese, or sour cream containers. Polypropylene is highly used in microwavable containers because it has a high melting point and can tolerate high heat.

Plastic Films

There are different kinds of plastic films, which have different qualities depending on the materials used when it is produced. The most common structures of plastic films are lidding, shrinking, VSP films, stand-up pouches, and specialty bags. They are very light in weight and highly resistant to any contamination. In addition, most plastic films can be printed on, which is an advantage for brands to improve their recognition and aesthetics. The most common plastic films are as follows:

Low-Density Polyethylene (LDPE) Film

This material is the cheapest of all the plastic films. It is very flexible, soft, and transparent. In addition, it is highly resistant to moisture, tearing, and chemicals. LDPE is mostly used to manufacture plastic bags, and it is also widely used to make food bottles that are flexible and squeezable; it is also used to manufacture bread and frozen food packaging and lids.

Linear Low-Density Polyethylene (LLDPE) Film

LLDPE has similar features to LDPE, but its characteristics include high tensile and impact strengths, and better and improved heat-preserving sealing qualities. In addition, LLDPE is the most flexible among the polythene sheeting varieties. In the food industry, it is used in shrink wraps and bottle caps.

Ultra Low-Density Polyethylene (ULDPE) Film

ULDPE is a thermoplastic that has low flexibility and flex crack resistance. In addition, it is tear resistant and has high optical clarity. It is mostly used to store cheese, meat, and coffee.

Medium-Density Polyethylene (MDPE) Film

This plastic film is not commonly used like the others. It is, however, stronger and more durable, allowing it to resist tears and punctures and infiltration of chemicals a lot more than LDPE, and it is oxygen permeable. MDPE is used to store baked goods; it is usually manufactured into wash bottles and heavy-duty produce bags.

High-Density Polyethylene (HDPE) Film

This is the most commonly used plastic to store food, especially in manufacturing industries for food packaging. HDPE is a polyethylene film that is semi-translucent and highly solvent-resistant. It is the least flexible of all the films, making it ideal for applications where it needs to hold a particular shape. HDPE is found in water, juice, or milk bottles, margarine and butter containers, and retail shopping bags.

Polypropylene Film

This plastic film is not transparent as compared to PET, but rather it is translucent, meaning it lets in light but one is unable to see through it. Its characteristics include high optical clarity, high gloss, good tensile strength, and it is cheap. It also has a high melting point and good barrier properties, making it ideal for food items that need high-temperature sterilization, like baby bottles. It is also used for microwavable kitchenware, salad dressing bottles, yogurt containers, and margarine tubs.

Polyvinyl Chloride (PVC) Film

PVC is an inexpensive, highly versatile thermoplastic. Its characteristics include rigidness or flexibility depending on its formulation, high impact strength, and good dimensional stability; it is also oxygen permeable and a barricade to oil and grease. It is used as tubing in beverage and food applications and as blister packaging for various food products.

Polyethylene Terephthalate (PET) Film

PET is a high-performance plastic and is used for making films. Its characteristics include high tensile strength, low moisture absorption, and exquisite dimensional stability in various wide-range temperatures. It is used in plastic bottles that store carbonated drinks, jars, tubs, and snack food wrappers.

Biaxially-Oriented Polyethylene Terephthalate (BOPET) Film

Bopet is a material made from stretched PET to create a polyester film. BOPET is commonly used as a faux foil packaging and protective film in microwavable films.

Polyvinylidene Chloride (PVDC) Film

PVDC is a synthetic thermoplastic with a great barrier in resisting moisture and oxygen. It also is highly resistant to heat, grease, and chemicals. It is commonly used in food and medicine packaging as it helps extend shelf life.

Polyamide (PA)/Nylon Film

It is mostly known as nylon. It is a very strong type of thermoplastic, and it has a high melting point which creates a good barrier making it resistant to oxygen infiltration. It does not dissolve or absorb grease, oil, or acidic foods. It is also resistant to punctures and provides flex crack resistance. This material is used in microwave and cooking applications.

Choosing the Correct Plastic Food Container Supplier

To ensure you have the most positive outcome when purchasing plastic food containers from a plastic food container supplier, it is important to compare several companies using our directory of plastic food container suppliers. Each plastic food container supplier has a business profile page highlighting their experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each plastic food container business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple food container companies with the same form.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

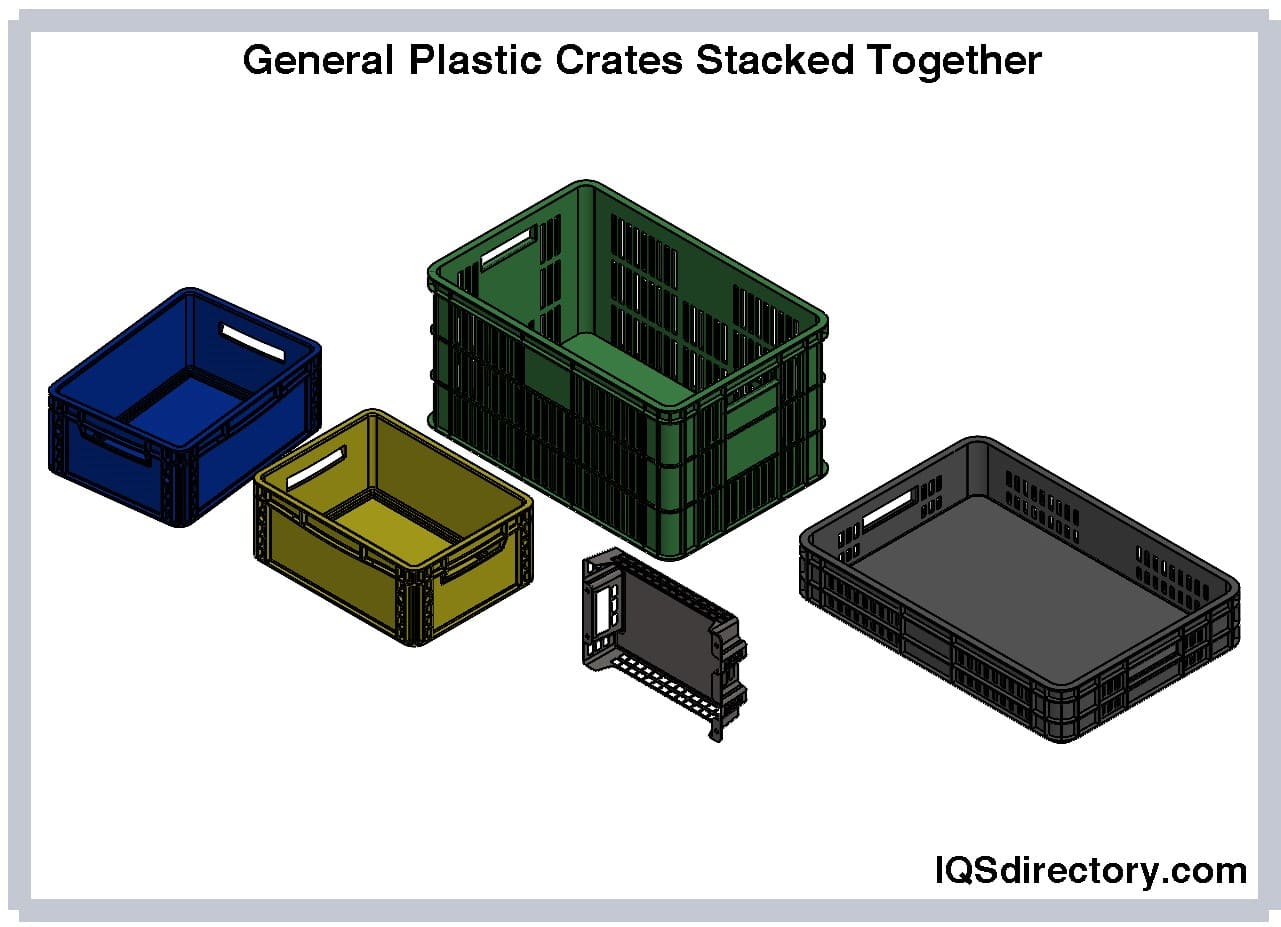

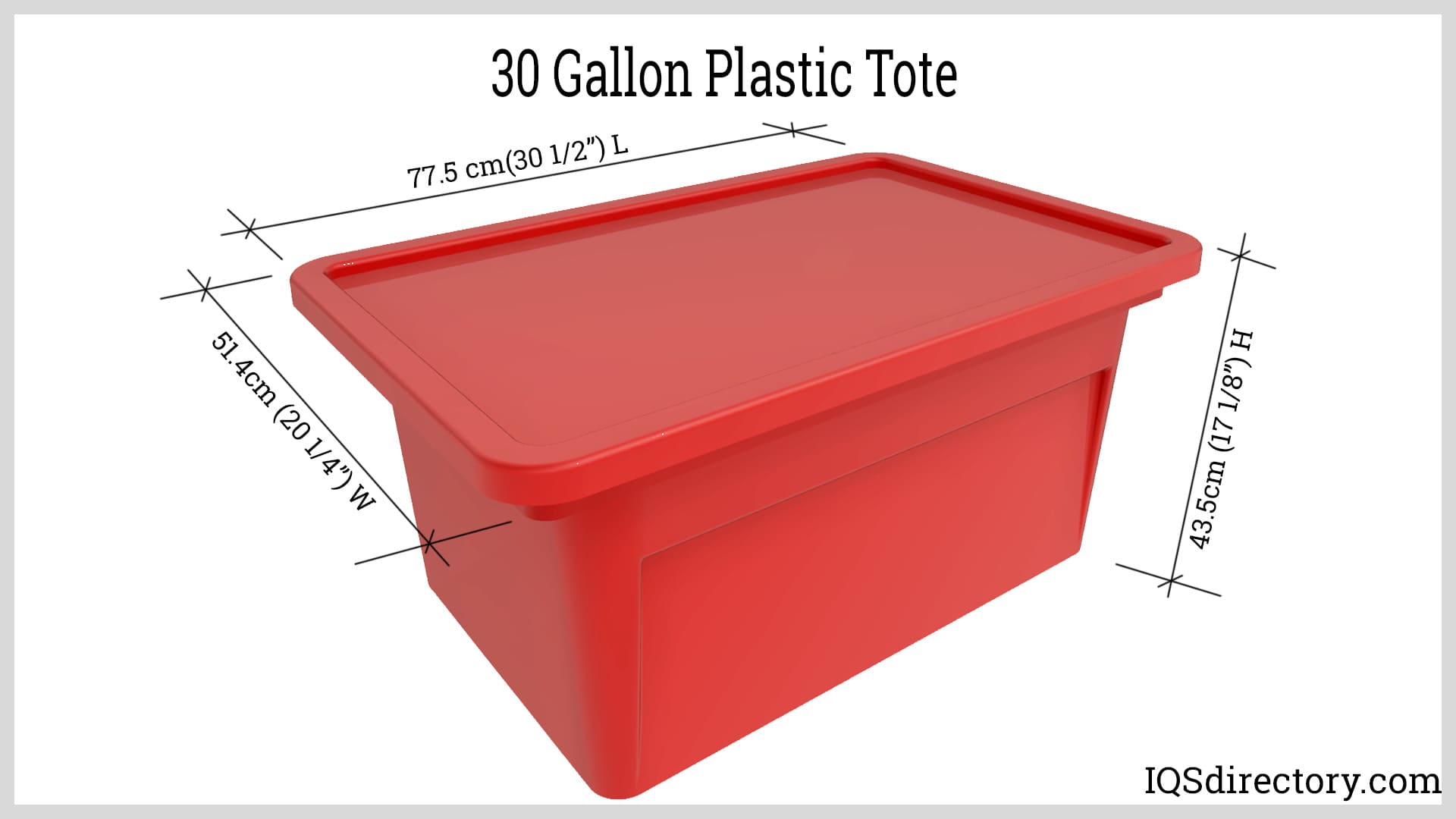

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services