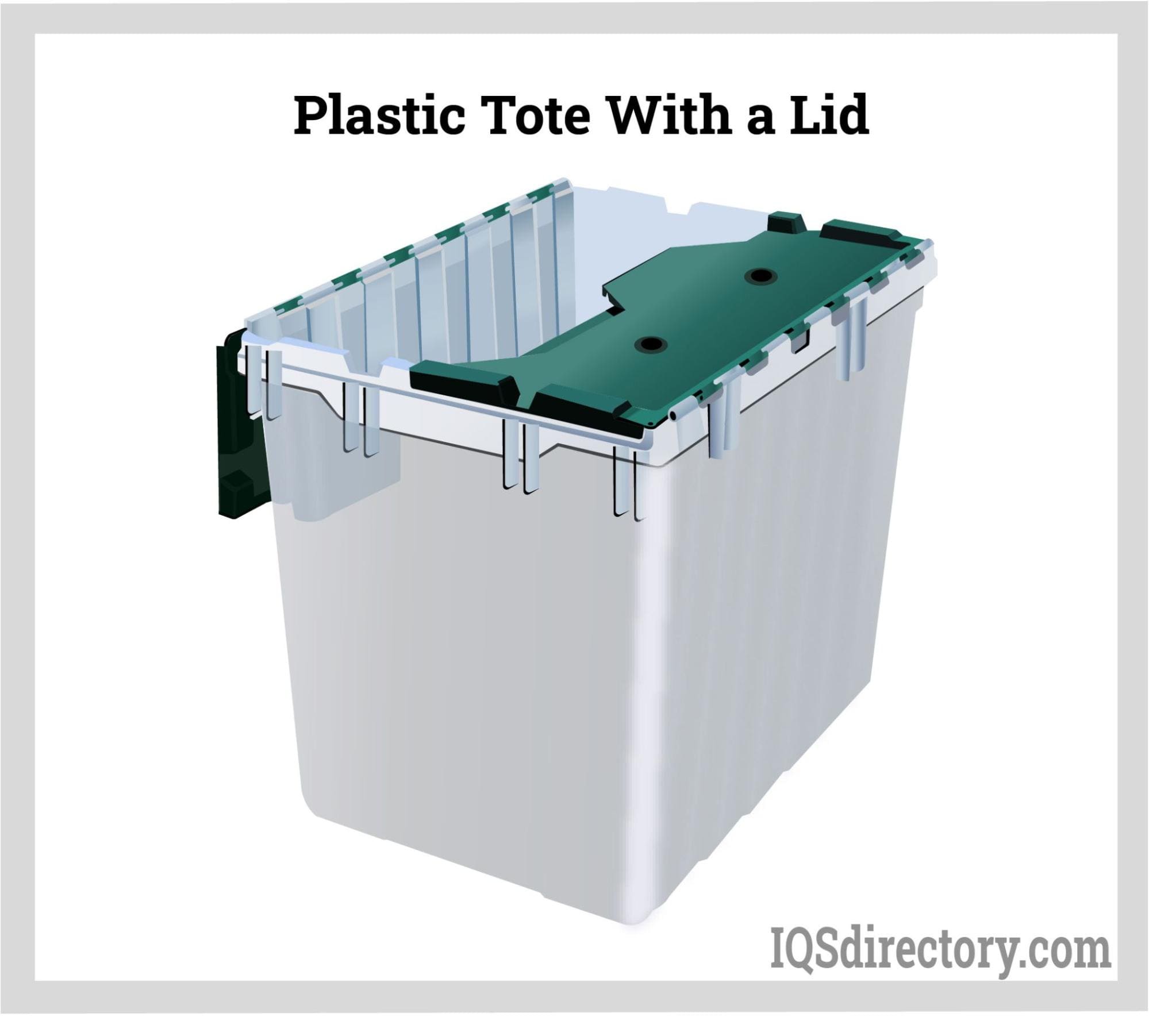

Totes are built in solid box shapes and are quite lucrative as industrial storage products that can be designed in a manner that allows them to be collapsed depending on the desired requirements to save space when they are not being used. Other plastic totes have hinged or removable tops, which can provide easy access for the user. Read More…

As a leader in the plastic container & plastic food container industry, Rahway Steel Drum Company supplies plastic storage containers, plastic shipping containers & more, to be used for regulated & non-regulated liquid & solid packaging. Choose from our many sizes from 1 quart to 330 gallons. For 60 years we have been a plastic container distributor of lightweight, space saving, bulk containers.

Jakacki Bag & Barrel, family owned and operated, is a plastic container manufacturer. Their products include pails, pallets, gaylords, drums and so much more.

Container Distributors offers a solution for all of your plastic container needs, including all sizes of new and reconditioned plastic containers, as well as steel and fibre drums. We also carry a wide range of cubic yard boxes and IBC/totes.

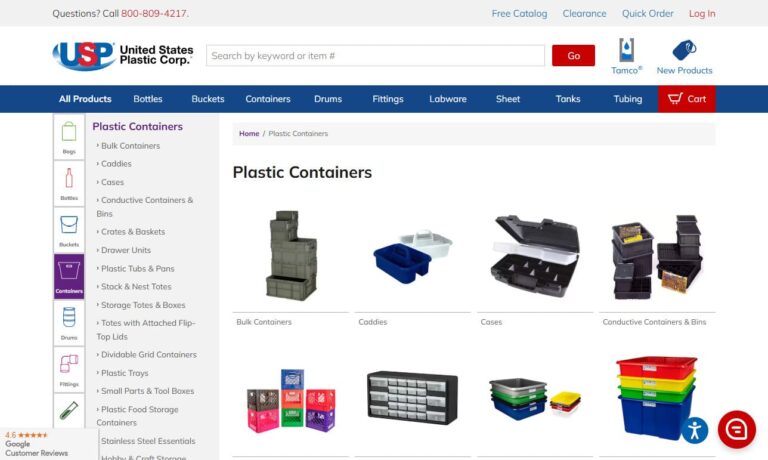

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

At BayTec Service, we specialize in providing high-quality plastic containers designed to meet the diverse needs of industries ranging from chemical processing to food storage and industrial manufacturing. We take pride in offering an extensive selection of durable, versatile containers that deliver long-term performance in demanding environments.

For the past 30 years, Western Industries has been manufacturing plastic containers for a variety of industries, and fulfilling the needs for businesses large and small. At our 350,000 square-foot manufacturing campus, we have the technology and the expertise to manufacture plastic containers of all shapes and sizes, defect-free.

More Plastic Tote Manufacturers

Features of Plastic Totes

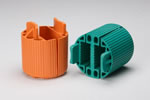

Plastic totes are essential storage and material handling solutions designed for a wide range of industries, including manufacturing, warehousing, logistics, food processing, healthcare, and retail distribution. Their popularity stems from their versatility, durability, and adaptability. Key features of plastic totes include their availability in various shapes, sizes, and colors, making them suitable for both general-purpose and specialized applications.

Many plastic totes are specifically sized to accommodate automated processing equipment, conveyors, and robotic pick systems—streamlining workflow automation in warehouses and distribution centers. Heavy-duty plastic totes are engineered to withstand rigorous use, offering resistance to impact, moisture, chemicals, and temperature fluctuations. Designs may include built-in legs for easy stacking, casters for mobility, or ergonomic handles for safe manual handling.

Small plastic totes are often designed to be stackable, maximizing storage density and supporting efficient inventory organization. Larger industrial plastic totes may feature reinforced corners, forklift-compatible bases, or openings that coordinate with pallet jacks for safe and efficient transport. Many plastic totes are manufactured from recyclable plastics and may be insulated or uninsulated, depending on their intended use. For applications in the pharmaceutical, food, or medical device industries, certain plastic totes are manufactured using FDA-approved or food-grade resins to meet strict regulatory standards.

Types of Plastic Totes

Plastic totes are available in a wide variety of designs to address the unique material handling, storage, and organizational needs of different industries. Understanding the specific types of plastic totes and their applications can help you select the best solution for your requirements. Below are some of the most common types of plastic totes:

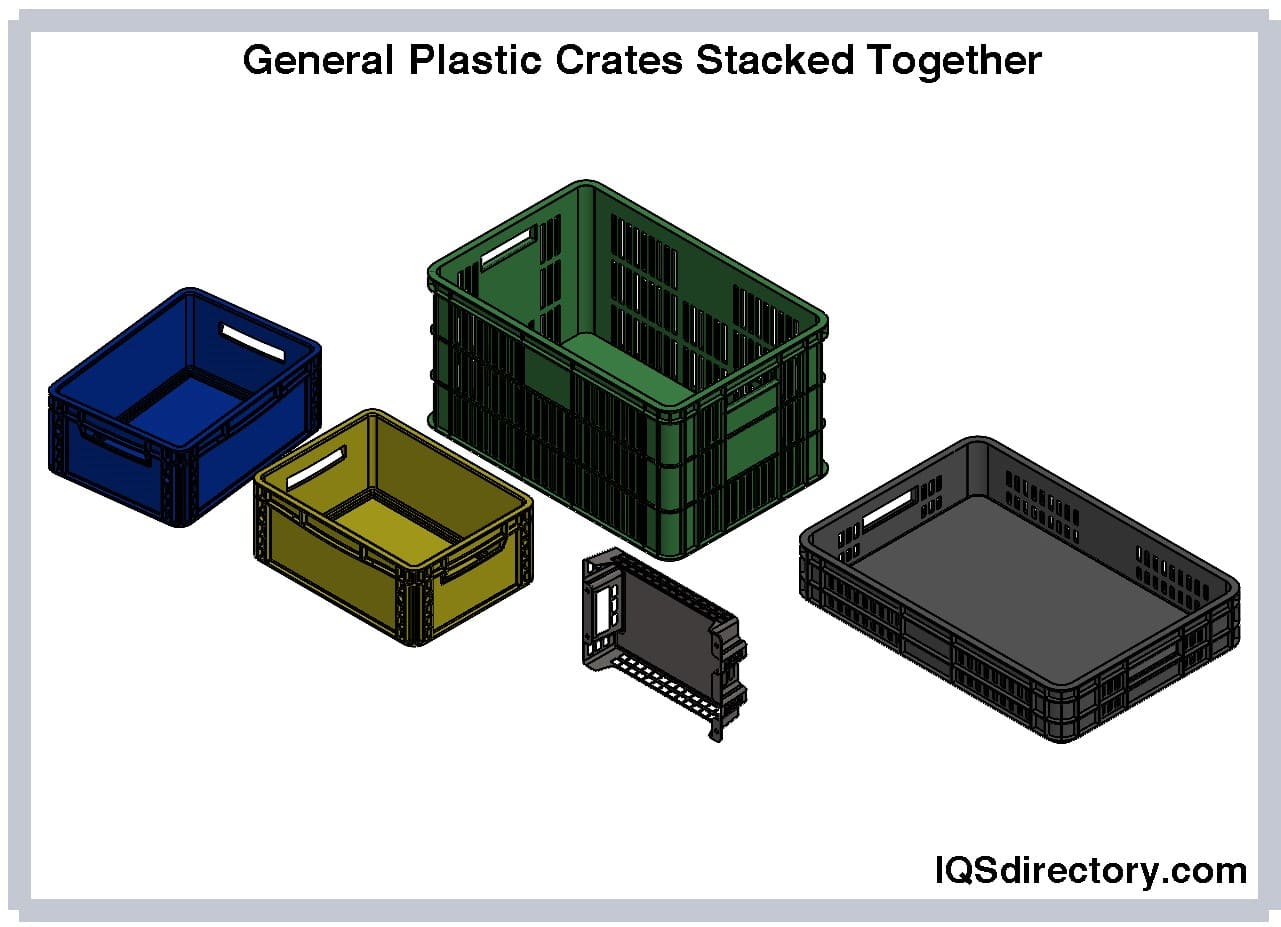

- Bulk Totes – Bulk plastic totes are engineered for maximum durability and strength. Resistant to corrosion, rust, warping, and splintering, these containers are ideal for storing and transporting large volumes of raw materials, ingredients, or finished goods. They are commonly used in agriculture, food processing, chemical handling, and recycling industries, thanks to their robust construction and chemical-resistant properties. Bulk totes are often compatible with automated handling systems and can be used for both dry and liquid products.

- Insulated Totes – As their name suggests, insulated plastic totes feature thermal insulation to maintain internal temperatures. This makes them perfect for the cold chain, food delivery, pharmaceutical storage, and shipping temperature-sensitive products. Insulated totes are available in various shapes and sizes, often featuring tight-fitting lids and double-walled construction. They help preserve freshness, prevent spoilage, and protect contents from temperature fluctuations during storage and transportation.

- Collapsible Totes – Collapsible plastic totes are designed for efficient storage and return logistics. Available in solid or vented versions, these containers can be folded flat when empty, dramatically reducing the space required for storage or return shipment. They are widely used in supply chain management, automotive parts distribution, and reusable packaging programs. Collapsible totes help lower transportation costs and support sustainability initiatives by minimizing empty container volume.

- Hand-Held Totes – Hand-held plastic totes are smaller, lightweight containers designed for easy carrying, stacking, and space-efficient storage. Their ergonomic design makes them ideal for order picking, assembly lines, retail restocking, and inventory management in distribution centers. These totes are available in multiple sizes and can include features such as attached lids, label holders, and reinforced bottoms. Their versatility and durability make them a staple in many industries.

Plastic Totes Information & Product Specifications

When researching or purchasing plastic totes, it’s important to consider a range of product specifications to ensure the chosen solution meets your unique operational needs. Here are some of the key factors to evaluate:

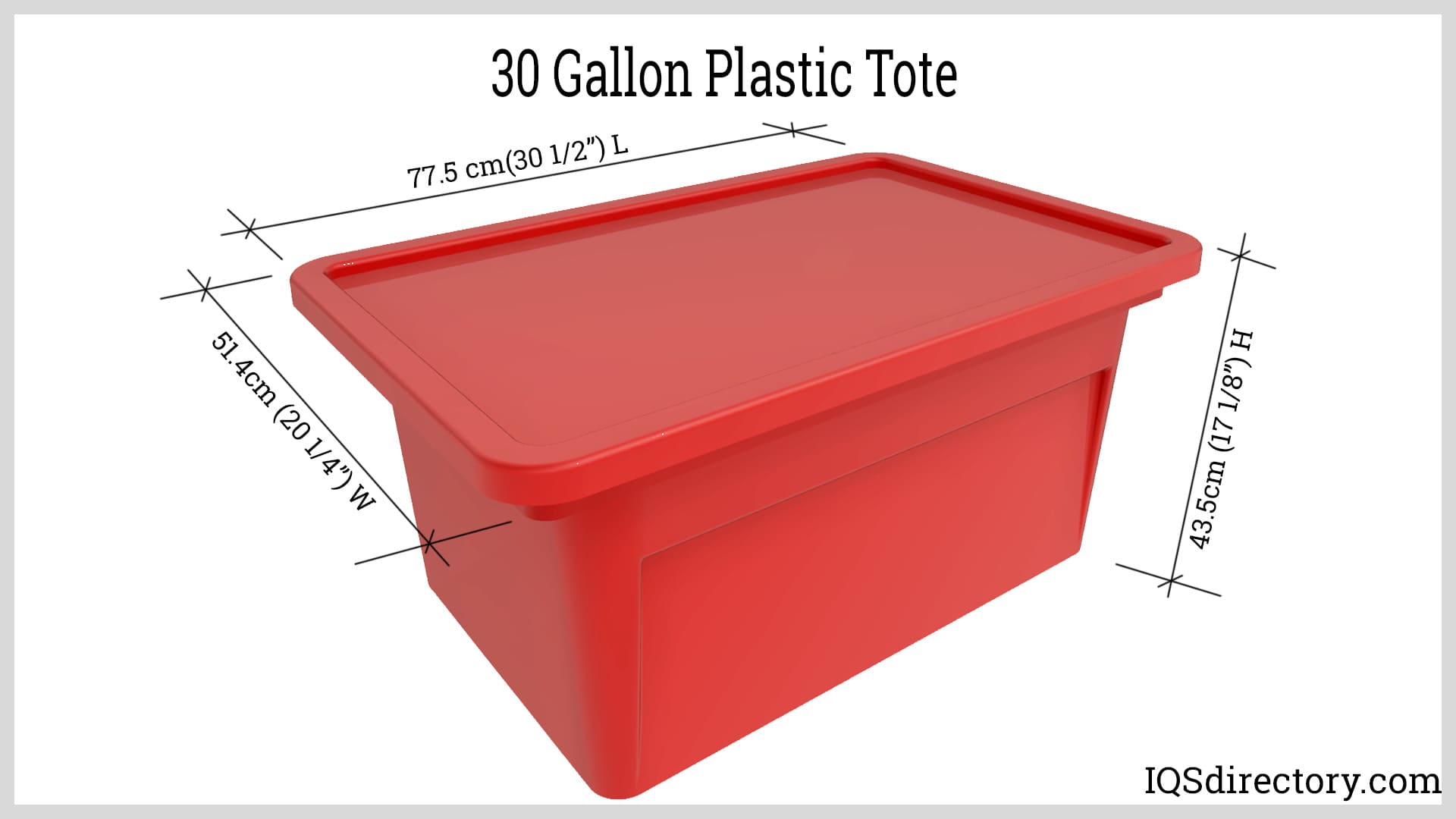

- Volume Capacity: Choose plastic totes with the right internal volume to accommodate your products or materials while supporting efficient storage and handling.

- Depth or Length: Select totes with suitable length and depth to fit shelving, racks, or automated systems in your facility.

- Width or Diameter: Consider the width or diameter for compatibility with conveyor belts, picking systems, and storage units.

- Height: The height of a tote impacts stacking, accessibility, and storage density.

- Color: Many manufacturers offer totes in a variety of colors to support color-coding, process management, or brand identification.

- Material: Totes are produced from a variety of plastics, each offering unique properties such as chemical resistance, impact strength, and temperature tolerance.

Are you wondering how to select the right plastic tote for your business? Consider factors such as load capacity, intended application, storage environment, and compatibility with existing equipment. For industry-specific guidance or to compare leading plastic tote models, explore our directory of plastic tote suppliers or request a custom quote.

Plastics Used to Make Totes

The choice of material is crucial in determining the performance, longevity, and suitability of a plastic tote for specific applications. Most plastic totes are manufactured from advanced polymers and engineered plastics, each selected for their unique strengths and characteristics. Here are some common materials used in the production of plastic totes:

- Polyethylene (PE): High-density polyethylene (HDPE) and low-density polyethylene (LDPE) are popular for their impact resistance, flexibility, and chemical inertness. HDPE plastic totes are widely used in food processing, agriculture, and chemical manufacturing due to their toughness and moisture resistance.

- Polypropylene (PP): Known for its superior resistance to cracking, chemicals, and high temperatures, polypropylene is often used in totes that require frequent cleaning or exposure to harsh environments. PP totes are lightweight, durable, and suitable for both reusable and returnable packaging systems.

- Polyvinyl Chloride (PVC): PVC is a chemically inert material often chosen for food-grade totes, laboratory storage, and chemical processing applications. Its resistance to acids, alkalis, and biological contaminants makes it ideal for sensitive environments.

- Acrylates & Acrylics: Acrylic-based plastic totes are valued for their clarity, dimensional stability, and customizable aesthetics. These are often used when visual identification of contents is important.

- Acrylonitrile Butadiene Styrene (ABS): ABS provides excellent dimensional stability and is a stiff thermoplastic polymer, commonly used for impact-resistant totes in manufacturing and distribution facilities.

- Fiberglass, Wire, and Metals: While not plastics, these materials are sometimes used for hybrid totes or specialized storage containers where additional strength or conductivity is required.

Which plastic tote material is best for your needs? Ask yourself about your handling environment—do you need food-grade, static-dissipative, or heavy-duty industrial plastic totes? Our plastic tote material comparison guide can help you decide.

Benefits of Using Plastic Totes

Plastic totes offer a host of advantages over traditional storage and shipping containers made from materials like cardboard, wood, or metal. Their widespread adoption in industries across the globe is a testament to their reliability and value. Here are some of the top benefits of using plastic totes for your organization:

- Easy Installation and Handling: Collapsible plastic totes and stackable designs facilitate quick setup and breakdown, reducing labor costs and downtime.

- Cost-Effective & Efficient: Plastic totes lower supply chain expenses by enabling reusable, long-lasting storage and transport solutions. Their durability means fewer replacements and lower total cost of ownership.

- Organizational Versatility: Use plastic totes to segregate, sort, and store a wide array of small parts such as bolts, nuts, screws, and assembly components. Custom dividers and compartmentalization options increase efficiency.

- Enhanced Safety & Accessibility: Plastic totes improve workplace safety by minimizing clutter and providing easy access to contents when needed. Smooth surfaces and rounded corners reduce the risk of injury.

- Space-Saving Stackability: Their ability to be stacked—either nested or with lids—maximizes storage density in warehouses, distribution centers, and retail backrooms.

- Environmental Sustainability: Many plastic totes are made from recyclable materials and can be reused hundreds of times, supporting zero-waste initiatives and reducing environmental impact.

- Long-Term Storage Solution: Resistant to moisture, pests, and corrosion, plastic totes are ideal for both short-term and long-term storage needs.

- Security & Tamper-Resistance: Many totes feature swing-open lids that can be locked or sealed for secure storage, tamper-evident applications, and inventory control. Optional molded legs or reinforced bases add stability.

Curious about how plastic totes can improve your supply chain efficiency or workplace organization? Explore common applications and learn how industry leaders are leveraging plastic totes for cost savings and operational excellence.

Applications of Plastic Totes

Plastic totes have become a material handling staple across dozens of industries, thanks to their adaptability, durability, and cost-effectiveness. Below are some of the most common and high-value applications for plastic totes:

- Manufacturing & Assembly: Plastic totes are used for parts storage, kitting, work-in-process handling, and component delivery to assembly lines. Their standardized sizes integrate seamlessly with automated systems and conveyors.

- Warehousing & Distribution: In logistics and e-commerce fulfillment centers, plastic totes support efficient picking, packing, order consolidation, and inventory management. Their stackability and barcode compatibility streamline the flow of goods.

- Food & Beverage: Food-grade plastic totes are indispensable for storing, transporting, and processing seafood, poultry, meats, fruits, and vegetables. Insulated totes help maintain the cold chain and preserve product quality from farm to table.

- Pharmaceutical & Healthcare: Medical-grade plastic totes are used for transporting medications, medical devices, and sensitive pharmaceuticals under sterile or temperature-controlled conditions. Compliance with FDA and health regulations is crucial.

- Electronics Manufacturing: ESD-safe (electrostatic discharge) plastic totes protect sensitive electronic components during assembly, testing, and shipping.

- Retail & Merchandising: Retailers use plastic totes for backroom storage, shelf replenishment, and point-of-sale displays due to their clean appearance and ease of handling.

- Recycling & Waste Management: Robust, easy-to-clean plastic totes are used for collecting recyclables, industrial scrap, and hazardous waste in commercial, municipal, and institutional settings.

- Shipping & Transportation: Plastic totes are a preferred alternative to cardboard boxes for shipping due to their durability and reusability. They reduce packaging waste and withstand the rigors of extended supply chains.

- Cold Storage & Temperature-Controlled Logistics: Insulated and non-insulated totes are used for transporting temperature-sensitive goods, ensuring compliance with cold chain protocols.

Looking for ideas on how to implement plastic totes in your operation? Review our industry-specific plastic tote applications for inspiration and best practices.

How to Choose the Best Plastic Tote for Your Application

Selecting the correct plastic tote is critical to maximizing efficiency, safety, and cost-effectiveness in your workflow. Here are the key decision factors to consider when evaluating plastic tote options:

- Intended Use: Are you looking for totes for food processing, warehouse storage, shipping, or cleanroom applications? Each use case may require different materials, sizes, and features.

- Load Capacity: Assess the weight and type of products or materials you'll be storing or transporting to ensure the tote can safely handle the load.

- Stacking & Nesting: Choose between stackable, nestable, or collapsible designs based on your storage density and return logistics requirements.

- Material & Compliance: Select FDA-approved, food-grade, or ESD-safe plastics as needed for your industry. Check for compatibility with sterilization, cleaning, or sanitation processes.

- Customization: Many manufacturers offer custom sizes, colors, branding, and accessory options (lids, dividers, casters, handles) to meet specific needs.

- Budget & Lifecycle Cost: Consider not just the purchase price, but also the tote’s lifespan, reusability, and total cost of ownership.

- Supplier Reputation: Work with an experienced plastic tote manufacturer or distributor known for quality, compliance, and customer service.

Need help evaluating your options? Ask, “What size plastic tote do I need for my storage system?” or “Which plastic tote is best for food processing?” Our plastic tote supplier directory connects you directly with trusted manufacturers for personalized recommendations.

Choosing the Correct Plastic Tote Manufacturer

To ensure you achieve the most productive outcome when purchasing plastic totes, it’s essential to compare several reputable plastic tote manufacturers and suppliers. Our directory of plastic tote manufacturers streamlines this process by providing detailed business profiles, areas of expertise, and product offerings.

- Company Profiles: Each manufacturer profile highlights their experience, capabilities, certifications, and specializations, such as food-grade, heavy-duty, or custom plastic tote solutions.

- Direct Communication: Use integrated contact forms to request information, product samples, or a quote directly from each manufacturer.

- Website Previewer: Quickly review each company’s website using our proprietary previewer to understand their product range and value proposition.

- Streamlined RFQ: Submit your requirements to multiple plastic tote suppliers simultaneously using our simple RFQ (Request for Quote) form.

- Compare & Save: Evaluate pricing, lead times, customization options, and customer support to make an informed purchasing decision.

Ready to find the perfect plastic tote supplier? Browse our directory or contact us for expert assistance in selecting the best plastic tote manufacturer for your project.

Frequently Asked Questions About Plastic Totes

- What are the key differences between collapsible, stackable, and nestable plastic totes?

Collapsible totes fold flat for return transport, stackable totes are designed to be placed one atop another when full, and nestable totes fit inside each other when empty to save space. - How do I determine the correct size and type of plastic tote for my operation?

Assess your storage space, material flow, automation compatibility, and product dimensions to select the optimal tote. Consult with manufacturers for standard and custom sizing. - Are plastic totes suitable for cold storage or freezer applications?

Yes, many plastic totes are engineered for cold storage, with materials and designs that withstand freezing temperatures. Insulated options are available for extra protection. - Can plastic totes be used for food contact?

Absolutely—look for food-grade or FDA-approved plastic totes for safe and compliant food handling. - What accessories are available for plastic totes?

Options include lids, dividers, label holders, casters, handles, and RFID/barcode tracking for inventory management. - How can I recycle or repurpose used plastic totes?

Many totes are made from recyclable plastics. Contact your supplier or local recycling facility for guidelines, or consider repurposing totes for secondary storage or donation.

Still have questions about plastic totes? Contact our experts or browse our supplier directory for answers, pricing, and product details.

Conclusion: Streamline Your Operations with Plastic Totes

Plastic totes are a proven solution for improving organization, efficiency, and sustainability in virtually every industry. Their adaptability, strength, and reusability make them an excellent investment for businesses aiming to optimize workflows, reduce costs, and meet environmental goals. Whether you need bulk storage bins, insulated shipping containers, or stackable hand-held totes, there’s a plastic tote designed for your unique requirements.

Ready to upgrade your storage or material handling process? Start your search for industry-leading plastic tote manufacturers and take the next step toward a more streamlined, sustainable operation.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services