More Plastic Container Manufacturers

History of Plastic Containers

Plastic containers represent one of the most transformative innovations in modern packaging and storage. The history of plastic, a synthetic substitute for natural resins, dates back to 1862, when Alexander Parkes unveiled the first plastic material—Parkesine—at an international exhibition in London. Derived from cellulose, this early form of plastic marked a new era in material science, paving the way for revolutionary advances in packaging technology. Just thirteen years later, plastic bottles entered the market, and by the early twentieth century, chemists had developed fully synthetic bottles. However, due to high production costs and limited scalability, early plastic packaging failed to rival glass and ceramic alternatives in economic impact.

It was not until the mid-twentieth century that plastic packaging began to change everyday life. In 1946, Earl Tupper introduced polyethylene containers branded as Tupperware®, which revolutionized food storage with their airtight, durable, and reusable properties. These plastic containers quickly became household staples, setting new standards for convenience and freshness.

In parallel, Dr. Jules Montenier made waves in personal care packaging with “Stopette,” an underarm deodorant sold in plastic bottles. This innovation demonstrated the versatility and practicality of plastic bottles, leading to widespread adoption in the cosmetics and pharmaceutical industries. By the 1960s, polyethylene bottles dominated packaging for food, beverages, and household products, and the 1970s saw the introduction of two-liter and single-gallon plastic bottles for sodas and milk, respectively.

As the 21st century approached, the plastic container industry faced new challenges and opportunities. Increasing environmental awareness and consumer demand for sustainable packaging encouraged the development of bioplastics, such as polylactic acid (PLA), a compostable polymer derived from renewable resources like corn starch. This shift towards eco-friendly plastic containers reflects ongoing innovation and a commitment to reducing the environmental footprint of packaging.

Want to learn more about the evolution of plastic packaging? Explore the detailed history of plastic containers and their impact on modern supply chains.

Production of Plastic Containers

The manufacturing process for plastic containers is a sophisticated blend of chemistry, engineering, and industrial design. Most plastics used in containers stem from hydrocarbons refined from petrochemical sources such as crude oil and natural gas. Key raw materials—including vinyl chloride, ethylene, glycol, and styrene—are synthesized into various polymers, the building blocks of both thermoplastics and thermosets.

Thermoplastics, including polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET), dominate the plastic container market due to their ability to be melted and reshaped multiple times. In contrast, thermosetting plastics, once cured, cannot be remolded, limiting their application in packaging. Today, the vast majority of plastic storage containers and packaging products are made from thermoplastics, thanks to their versatility and recyclability.

The plastic container production process typically involves two key molding techniques: injection molding and blow molding:

- Injection Molding: Plastic resins are fed into a hopper, where a rotating screw pushes the material through a heated barrel. The molten plastic is then injected into a custom mold cavity, forming precise parts such as lids, tubs, or bins. This method is ideal for producing large quantities of uniform, high-strength containers.

- Blow Molding: Particularly suitable for hollow items like bottles and jugs, this process inflates a heated plastic tube (parison) inside a mold using compressed air. The plastic conforms to the mold’s shape, then cools and solidifies. Blow molding provides excellent consistency and is the preferred method for manufacturing bottles, jars, and fluid containers.

Other advanced techniques, such as rotational molding and thermoforming, are used for specialized containers. Biodegradable and compostable options, including PLA and other bio-based polymers, are increasingly incorporated into product lines to meet sustainability requirements.

Types of Plastic Containers

The plastic container category encompasses an incredibly diverse array of products, each designed for specific uses, shapes, and environments. At its core, a plastic container is simply an enclosure made of plastic to store, protect, or transport goods. This broad definition includes everything from open bowls and stackable bins to airtight jars and heavy-duty drums.

Plastic containers are commonly classified by:

- Shape and Form: Bottles, jars, cups, bowls, cartons (such as egg cartons), pails, cans, squeeze tubes, trays, basins, bins, and more. Bottles and jars alone comprised 77% of all plastic container production by weight in the United States in 2011.

- Material Composition: The chemical makeup determines strength, transparency, recyclability, and food safety. The most prevalent material is thermoplastic polyethylene, especially PET (polyethylene terephthalate), which accounts for 96% of plastic containers in the U.S. due to its durability and moisture resistance.

- Function and Application: Food storage, beverage packaging, pharmaceutical vials, industrial bins, shipping crates, and even consumer goods like cosmetic jars and detergent bottles.

Key plastic types used in container manufacturing include:

- High-Density Polyethylene (HDPE): Used in medicine bottles, milk jugs, detergent containers, and industrial drums due to its strength and chemical resistance.

- Low-Density Polyethylene (LDPE): Flexible and tough, ideal for squeeze bottles, food wraps, and lids.

- Polyvinyl Chloride (PVC): Used for clear food trays, clamshell packaging, and shrink wraps. Noted for its clarity and versatility.

- Polypropylene (PP): Commonly found in fruit and vegetable packaging, microwave-safe containers, and laboratory bottles due to its heat resistance.

- Polystyrene (PS): Used for disposable cutlery, yogurt cups, and rigid transport containers.

- Bioplastics (PLA, PHA): Eco-friendly alternatives made from renewable resources, suitable for compostable packaging solutions.

Plastic wraps, though not rigid containers, are often grouped in the plastic container category due to their vital role in preserving and protecting products.

Applications of Plastic Containers

Plastic containers are indispensable across virtually every industry, offering reliable, cost-effective packaging and storage solutions. Their adaptability, durability, and lightweight nature make them essential for:

- Food and Beverage: Plastic bottles, jars, tubs, freezer containers, and wraps maintain product freshness, prevent contamination, and facilitate convenient portioning and transport.

- Pharmaceutical and Medical: Secure, sterile packaging for medicines, syringes, diagnostic kits, and specialized chemicals. Child-resistant caps and tamper-evident seals further enhance safety.

- Cosmetics and Personal Care: Bottles, tubes, and jars for lotions, creams, deodorants, and shampoos offer attractive branding and safe dispensing.

- Industrial and Chemical: Large plastic bulk containers, pails, and drums store and transport lubricants, adhesives, cleaning agents, and hazardous materials safely.

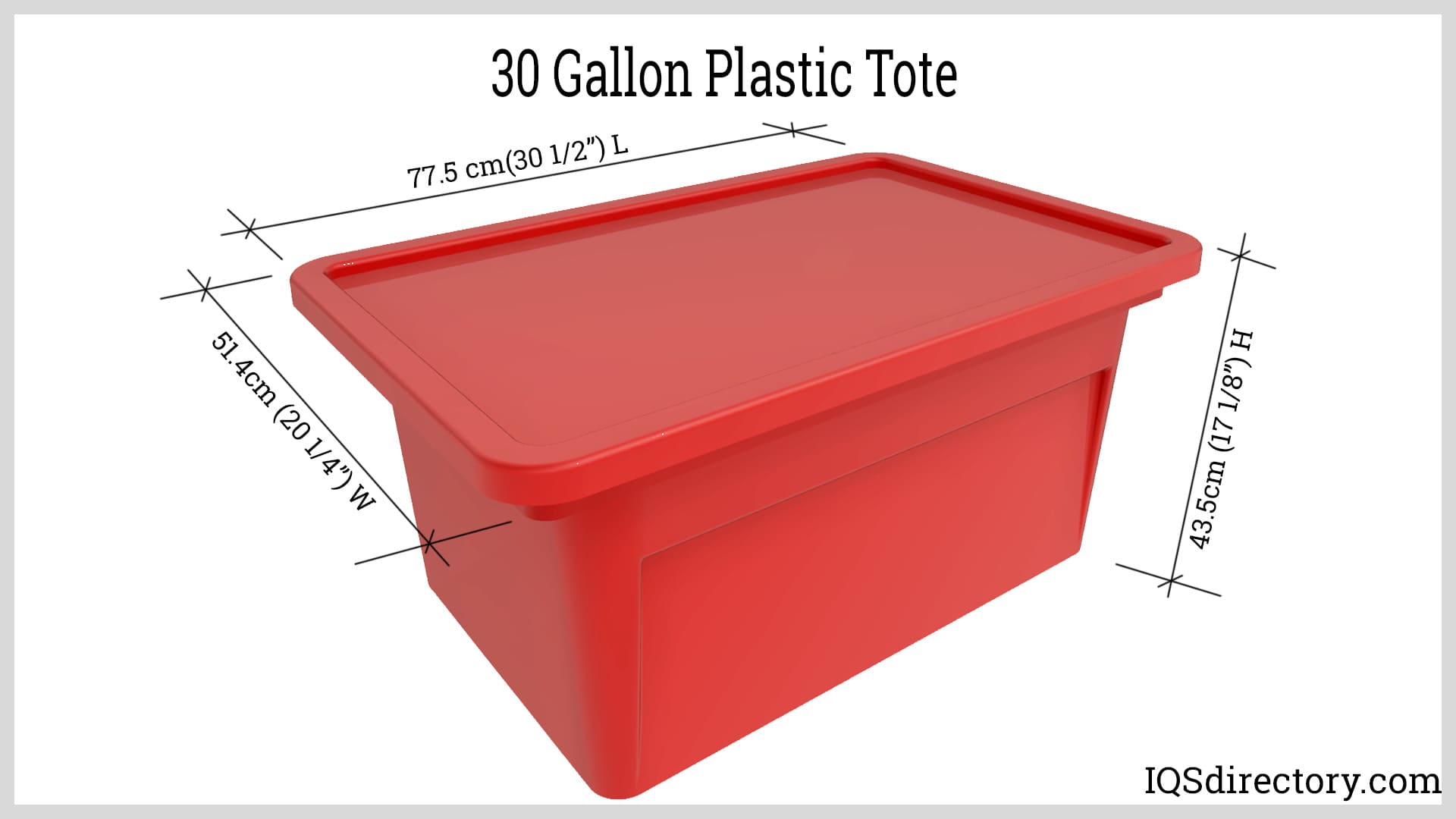

- Household and Consumer Goods: Storage bins, organizers, and stackable totes help maintain order in homes, offices, and retail environments.

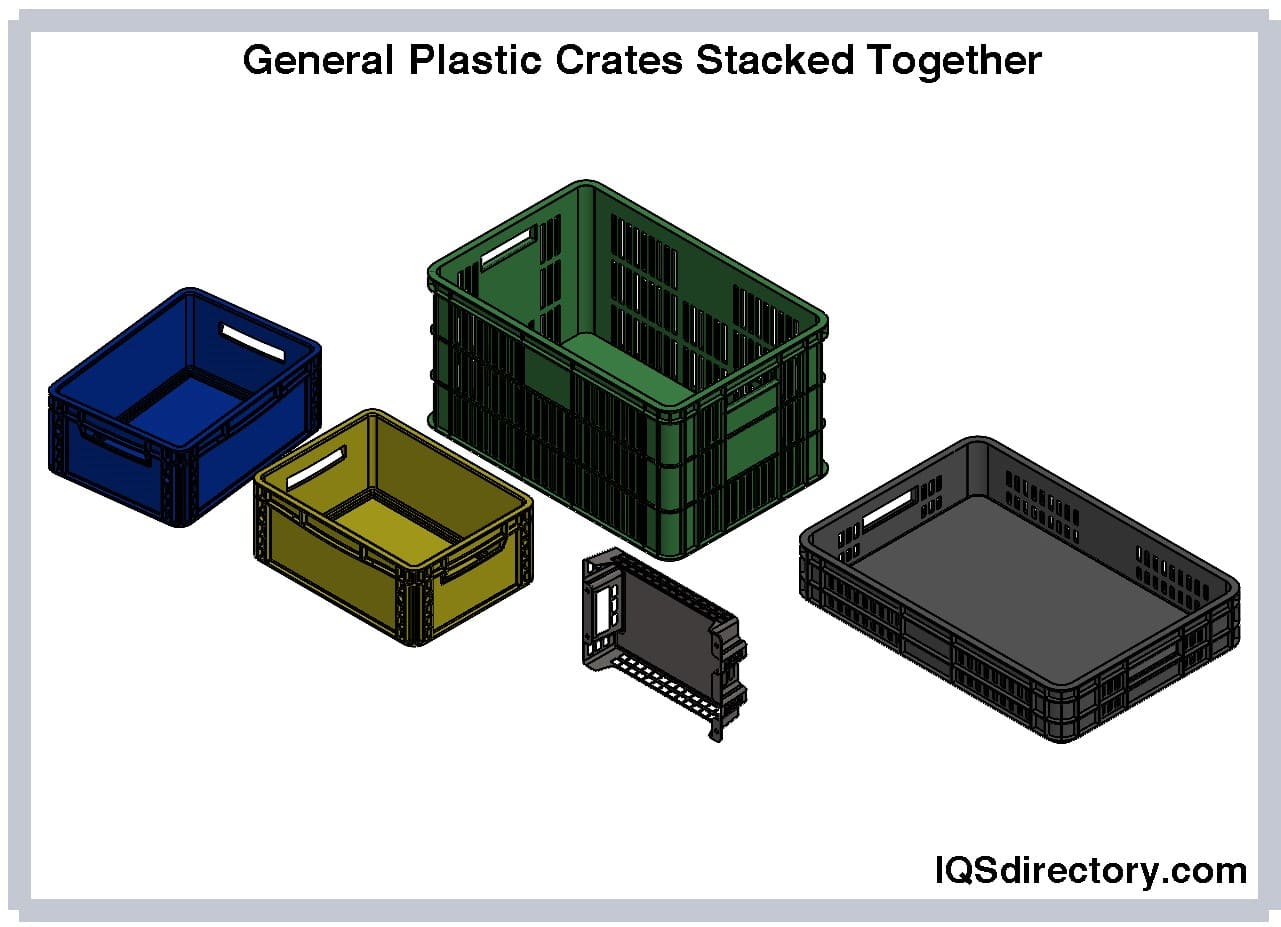

- Logistics and Distribution: Reusable plastic crates, pallets, and shipping totes streamline supply chain management and reduce packaging waste.

- Agriculture: Plastic cartons and crates are used for harvesting, storing, and transporting produce efficiently and hygienically.

- Construction and Landscaping: Catch basins, mixing tubs, and specialty pails aid in material handling and environmental management.

In developing regions, plastic containers support basic needs by safely storing scarce food and water resources. In industrialized nations, they underpin large-scale food distribution, pharmaceutical supply chains, and consumer product logistics.

Plastic containers are also central to recycling systems. Collection bins and reusable totes help close the loop, encouraging responsible disposal and facilitating the use of recycled plastics in new container production.

Benefits and Drawbacks of Plastic Containers

The widespread use of plastic storage boxes and containers is driven by a host of compelling benefits:

- Cost Savings: Durable, reusable plastic containers reduce long-term supply chain expenses and can replace hundreds of single-use cartons or boxes.

- Space Efficiency: Stackable, nestable, and customizable designs optimize warehouse and retail space, improving logistics and reducing transportation costs.

- Product Protection: Airtight lids and dust-resistant seals safeguard contents from moisture, contamination, and damage, ensuring product integrity.

- Durability: Made from high-strength, lightweight, waterproof, and UV-resistant materials, plastic containers outlast cardboard and wood alternatives in demanding environments.

- Versatility: Plastic containers can be molded to virtually any shape or size for specialized uses, from small vials to industrial drums.

- Branding Opportunities: Easy printing and color customization support brand identity and product differentiation on retail shelves.

- Recyclability: Many plastic containers are now designed for recycling, and the use of recycled content is on the rise.

However, plastic containers also present several challenges and considerations:

- Environmental Impact: Most plastics are derived from non-renewable petroleum sources, and improper disposal contributes to pollution and marine life hazards. The proliferation of single-use plastics remains a global concern.

- Health Risks: Some synthetic additives, like BPA and phthalates, have raised concerns about long-term exposure. Growing regulations and consumer awareness are driving demand for BPA-free and food-safe materials.

- Waste Management: Effective recycling and waste reduction require robust systems and consumer participation. While recycling rates for plastic bottles have improved, overall plastic waste remains a challenge.

- Material Choices: Selecting safer and more sustainable options—such as LDPE over PVC or bioplastics over petroleum-based polymers—can mitigate risks and enhance brand reputation.

Innovations in biodegradable plastics, advances in recycling technology, and industry commitments to sustainability are helping to address these drawbacks. Companies are increasingly adopting eco-friendly packaging solutions and closed-loop recycling programs.

How can you improve the sustainability of your plastic packaging? Explore strategies for greener manufacturing and responsible sourcing.

Plastic Bottles: Design, Production, and Use Cases

Plastic bottles are among the most ubiquitous forms of plastic packaging, particularly in the beverage, food, pharmaceutical, and personal care sectors. Their design must balance aesthetics, branding, safety, and functionality—making them a critical component of modern product marketing and logistics.

The key materials used in plastic bottle manufacturing include:

- Polyethylene Terephthalate (PET): The most popular choice for single-use water and soda bottles, PET is valued for its clarity, strength, light weight, and resistance to microbial growth. It is also highly recyclable, making it suitable for circular economy initiatives.

- Polypropylene (PP): Favored for reusable bottles, PP offers excellent heat resistance, chemical stability, and the ability to produce vibrant colors. It is commonly used for sports bottles and baby bottles.

- Polyvinyl Chloride (PVC): Used for certain reusable bottles, PVC is durable and flexible but has fallen out of favor for food and beverage packaging due to health and environmental concerns.

- High-Density Polyethylene (HDPE): Widely used for milk jugs, juice bottles, and personal care products, HDPE is strong, lightweight, and recyclable.

- Bioplastics and Compostable Polymers: These are increasingly used for eco-friendly bottles and packaging, especially in markets with strong consumer demand for sustainability.

The manufacturing process for plastic bottles varies by intended use:

- Single-Use PET Bottles: Produced via an efficient blow molding process, these bottles are designed for cost-effective mass production and optimized for light weight and recyclability.

- Reusable PP or HDPE Bottles: Manufactured with additional structural features to enhance strength and longevity, these bottles can withstand multiple use and cleaning cycles, making them ideal for sports, travel, and food service applications.

Plastic bottles offer numerous advantages over alternatives like glass or metal, including reduced shipping costs, resistance to breakage, and flexible design options. They also serve as effective marketing tools, with custom shapes, colors, and labels supporting brand visibility and consumer engagement.

Plastic bottles are widely used for:

- Carbonated beverages, bottled water, and juices

- Condiments, sauces, oils, and salad dressings

- Personal care products like lotions, shampoos, and hand sanitizers

- Medicines, vitamins, and nutraceuticals

- Household cleaning solutions and industrial chemicals

Types of Plastic Bottles

Plastic bottles are categorized both by their polymer composition and by their intended use:

- PET (Polyethylene Terephthalate): Transparent, strong, shatterproof, and lightweight, PET bottles are the industry standard for sodas, juices, and water. They resist pressure and carbonation, making them ideal for sparkling beverages.

- HDPE (High-Density Polyethylene): Opaque, moisture-resistant, and non-reactive, HDPE bottles are used for milk, juice, household cleaners, and personal care products. They are easy to recycle and offer excellent chemical compatibility.

- LDPE (Low-Density Polyethylene): Flexible and tough, LDPE is used for squeeze bottles, dropper bottles, and specialty packaging requiring easy dispensing.

- MDPE (Medium-Density Polyethylene): Blending properties of HDPE and LDPE, MDPE offers flexibility, impact resistance, and reduced translucency—suitable for squeezy condiment bottles and specialty containers.

- PP (Polypropylene): Lightweight, heat-resistant, and available in a range of colors, PP bottles are ideal for food, beverages, medicines, and cosmetics requiring sterilization or microwave compatibility.

- Bioplastics: Made from renewable organic sources, these bottles are compostable and support brands committed to environmental responsibility.

Manufacturing temperatures and processes vary: Thermosetting plastics (used for some single-use bottles) are melted at high temperatures and cannot be remolded, while thermoplastics (used for reusable bottles) can be reheated and shaped repeatedly.

Working with Plastic Container Suppliers: Key Considerations

Choosing the right plastic container supplier or manufacturer is critical for ensuring product quality, regulatory compliance, and supply chain efficiency. When evaluating potential partners, consider the following factors:

- Industry Experience: Look for suppliers with a proven track record in your sector—whether food packaging, pharmaceuticals, industrial storage, or consumer goods. Industry expertise ensures familiarity with relevant standards and best practices.

- Manufacturing Capabilities: Assess whether the supplier offers a full range of production methods (injection molding, blow molding, thermoforming) and can accommodate custom designs, sizes, and materials.

- Quality Assurance: Confirm that the manufacturer adheres to rigorous quality control processes and holds certifications such as ISO 9001, FDA compliance (for food and pharma), and relevant sustainability labels.

- Sustainability Initiatives: Inquire about recycled content, bioplastics, and closed-loop programs. Responsible suppliers will support your sustainability goals and provide documentation for eco-friendly claims.

- Supply Chain Support: Reliable logistics, responsive customer service, and scalable production capacity are essential for meeting project timelines and adapting to changing demand.

- Regulatory Compliance: Ensure your supplier understands and adheres to local and international packaging regulations, especially for food contact, hazardous materials, or export markets.

Effective communication and collaboration with your supplier can help you navigate design choices, select appropriate materials, and optimize costs. Many leading manufacturers also offer custom container design services, rapid prototyping, and assistance with labeling and branding.

Ready to connect with top plastic container manufacturers? Browse our comprehensive directory of vetted suppliers and request quotes today.

Frequently Asked Questions About Plastic Containers

- What is the most sustainable plastic container option?

Bioplastics and containers made from recycled PET or HDPE offer lower carbon footprints and improved recyclability compared to traditional petroleum-based plastics. - Are plastic containers safe for food storage?

Most food-grade plastic containers are FDA-approved and BPA-free, but it’s important to verify certifications and select materials suitable for your specific application. - How can I recycle plastic containers?

Check local recycling guidelines for accepted container types and rinsing requirements. Many municipalities collect PET and HDPE bottles curbside, while specialty programs handle other plastics. - What are the latest trends in plastic container packaging?

Sustainable materials, lightweighting, smart packaging (QR codes/RFID), and improved barrier properties are driving innovation in the industry.

Have more questions about plastic containers? Contact our experts for personalized advice or request a quote for your next project.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services