Plastic crates are frequently used to move things from one point to another. These crates are made of plastic material which makes them durable, reliable, degradation resistant, and lightweight. Plastic crates are more expensive than wooden or cardboard crates but are much more durable and useful in numerous settings. Read More…

As a leader in the plastic container & plastic food container industry, Rahway Steel Drum Company supplies plastic storage containers, plastic shipping containers & more, to be used for regulated & non-regulated liquid & solid packaging. Choose from our many sizes from 1 quart to 330 gallons. For 60 years we have been a plastic container distributor of lightweight, space saving, bulk containers.

Jakacki Bag & Barrel, family owned and operated, is a plastic container manufacturer. Their products include pails, pallets, gaylords, drums and so much more.

Container Distributors offers a solution for all of your plastic container needs, including all sizes of new and reconditioned plastic containers, as well as steel and fibre drums. We also carry a wide range of cubic yard boxes and IBC/totes.

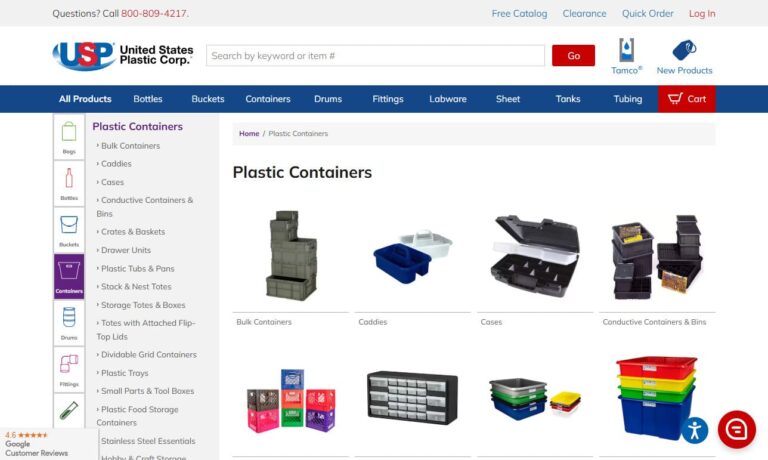

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

At BayTec Service, we specialize in providing high-quality plastic containers designed to meet the diverse needs of industries ranging from chemical processing to food storage and industrial manufacturing. We take pride in offering an extensive selection of durable, versatile containers that deliver long-term performance in demanding environments.

For the past 30 years, Western Industries has been manufacturing plastic containers for a variety of industries, and fulfilling the needs for businesses large and small. At our 350,000 square-foot manufacturing campus, we have the technology and the expertise to manufacture plastic containers of all shapes and sizes, defect-free.

More Plastic Crate Manufacturers

Design and Manufacturing Process of Plastic Crates

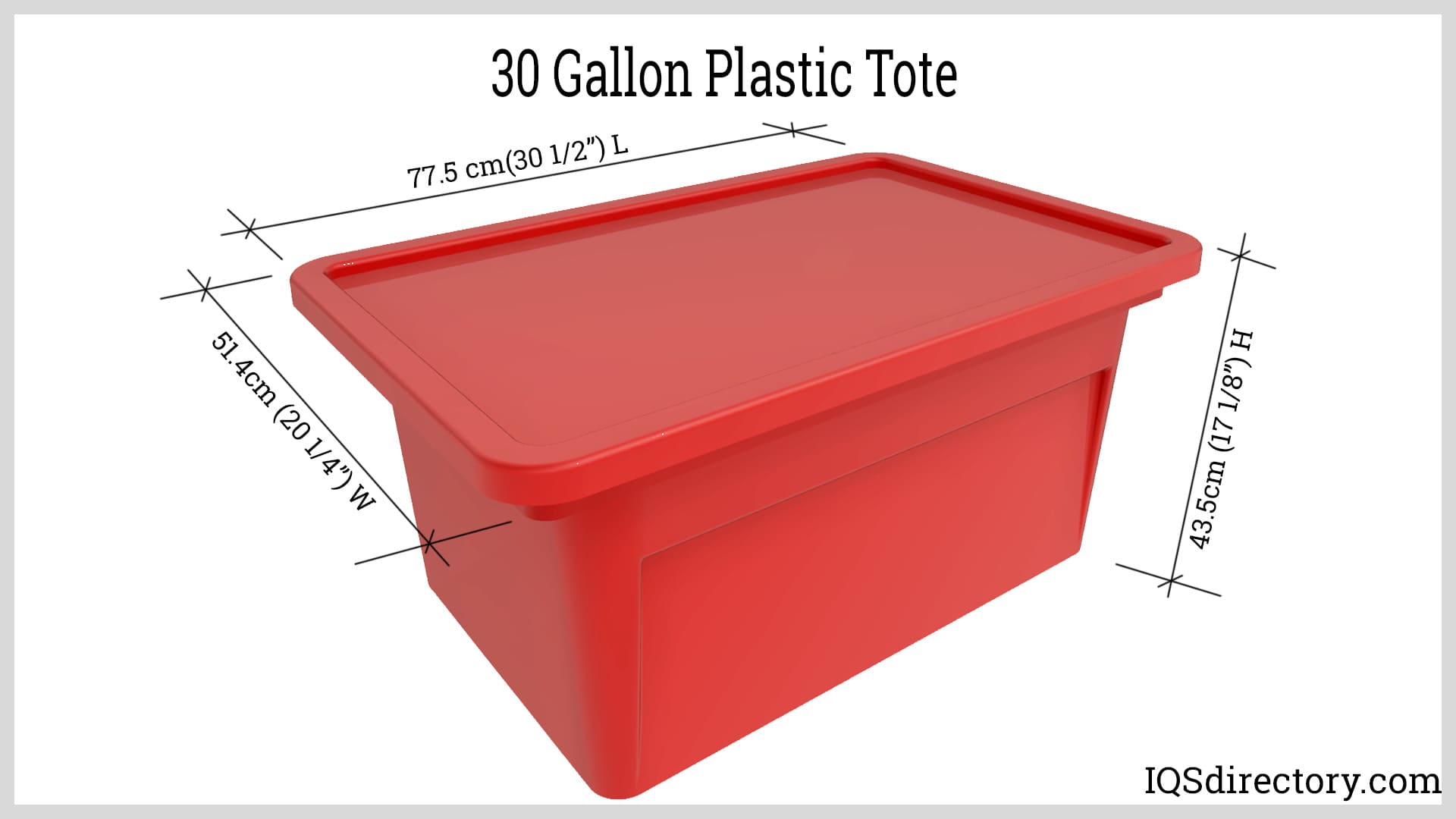

Plastic crates are essential storage and transportation solutions used across numerous industries, including agriculture, food processing, logistics, retail, and manufacturing. Available in a wide variety of types, sizes, colors, and shapes, plastic crates are engineered to withstand a diverse range of environmental conditions, weight loads, and impact stresses. Their versatility and durability make them indispensable for efficient material handling, product protection, and supply chain optimization.

Manufacturers select from several high-quality raw materials to produce plastic crates, with polypropylene (PP) and high-density polyethylene (HDPE) being the most common choices. Polypropylene offers exceptional scratch and abrasion resistance, making it ideal for crates that require frequent handling or sliding. In contrast, polyethylene is renowned for its superior impact strength, durability, and outstanding resistance to ultraviolet (UV) exposure, which is critical for outdoor applications and long-term storage. For enhanced performance, manufacturers often incorporate specialized additives such as antioxidants and UV stabilizers to both materials, increasing their longevity, resistance to fading, and ability to withstand harsh environments.

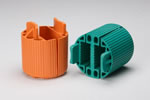

The plastic forming process chosen for crate production is determined by the desired shape, structural complexity, and intended use of the crate. Common plastic manufacturing methods include injection molding, blow molding, and rotational molding. Injection molding is widely used for producing high-precision, high-volume crates with intricate designs and consistent wall thickness. Blow molding is often selected for creating hollow or lightweight crates, while rotational molding is suitable for larger, thicker-walled containers. The choice of manufacturing technique impacts not only the crate’s mechanical properties and aesthetics, but also its cost, recyclability, and application suitability.

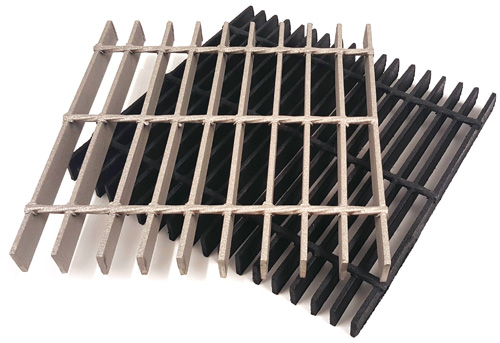

When designing plastic crates, manufacturers consider two fundamental configuration options: open and closed variants. Open plastic crates typically feature a grid or lattice pattern, allowing for clear visibility of contents and optimal airflow—an important factor for perishable goods. Closed plastic crates are designed with solid walls and may include removable or hinged lids to protect sensitive items from contamination, moisture, or mishandling. The choice between open and closed designs depends on the specific application, product type, and logistical requirements.

Plastic crates are especially in high demand within the food service, food delivery, and food processing sectors, where they are used to ship dairy products, baked goods, beverages, meats, seafood, and fresh produce safely and efficiently. Their reusability, ease of cleaning, and compliance with food safety standards make them the preferred choice over single-use alternatives.

Stacking Orientations of Plastic Crates

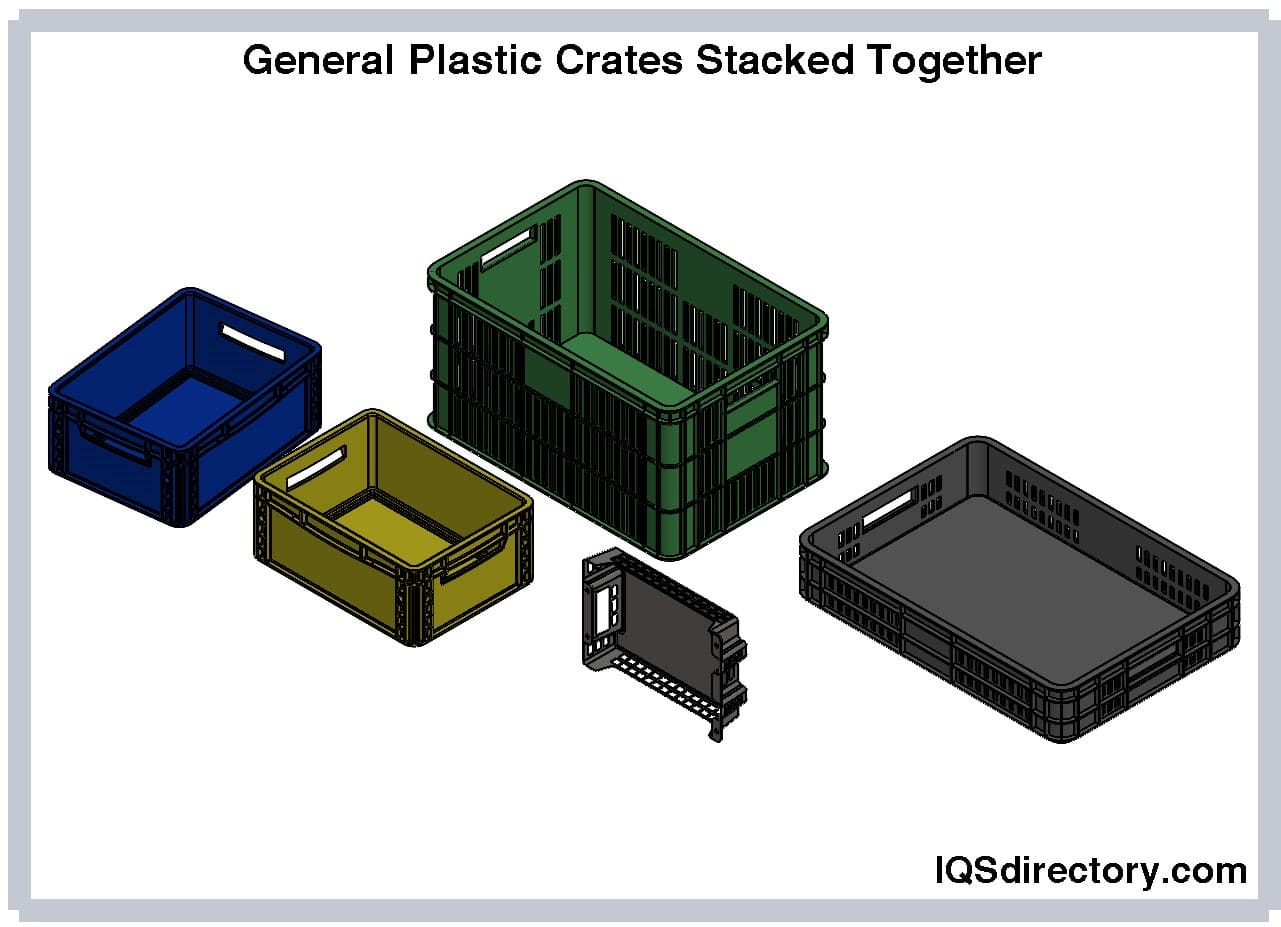

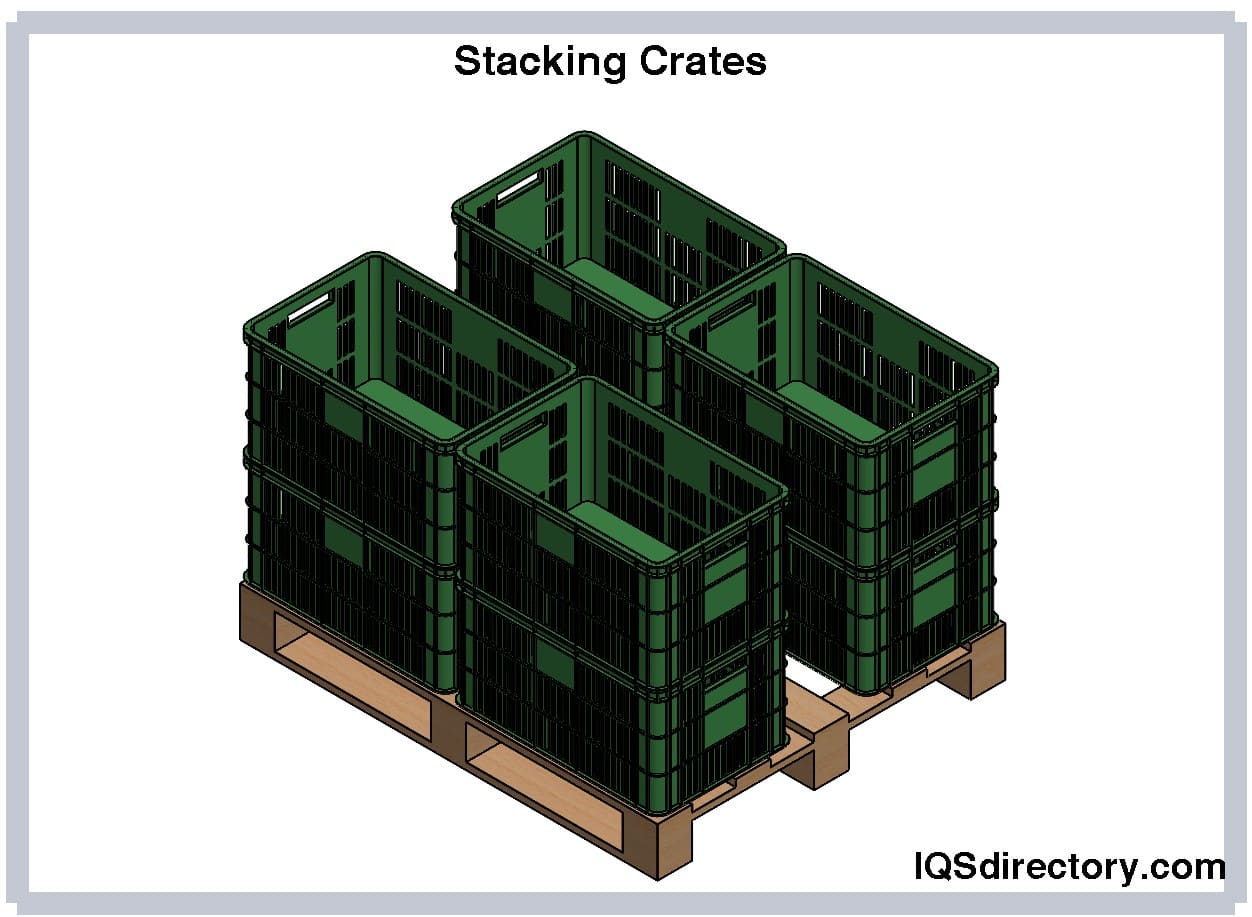

One of the most significant advantages of plastic crates lies in their space-saving stacking orientations, which directly affect their efficiency in storage, return logistics, and transport cost management. The three primary stacking configurations are collapsible/foldable crates, stacking crates, and stack-&-nest crates. Choosing the right stacking mechanism depends on your industry’s operational workflow, available storage space, and cost considerations.

- Collapsible Plastic Crates: These innovative crates are designed with hinged panels or folding mechanisms, allowing them to collapse flat when not in use. Collapsible crates are especially beneficial for companies seeking to minimize return shipping costs and maximize warehouse space. While they tend to be more expensive initially, their long-term savings in storage and logistics make them a smart investment for businesses with high crate circulation or limited storage capacity. Collapsible plastic crates are popular in distribution centers, e-commerce fulfillment, and reverse logistics operations.

- Stacking Crates: These crates feature square or rectangular shapes with reinforced corners, enabling secure stacking on top of one another. Stacking crates are the most cost-effective option for straightforward storage and shipping needs, as they are inexpensive to manufacture and purchase in large quantities. Their robust design and uniform dimensions make them ideal for automated handling, conveyor systems, and bulk storage in warehouses, retail backrooms, and manufacturing plants.

- Stack-&-Nest Crates: Stack-&-nest crates combine the benefits of efficient stacking when full and space-saving nesting when empty. Equipped with swing bars or handles, these crates can be stacked securely during use and nested inside each other for compact storage. This dual functionality reduces transportation volume and storage costs, making them a popular choice for grocery distribution, produce transport, and supply chain management.

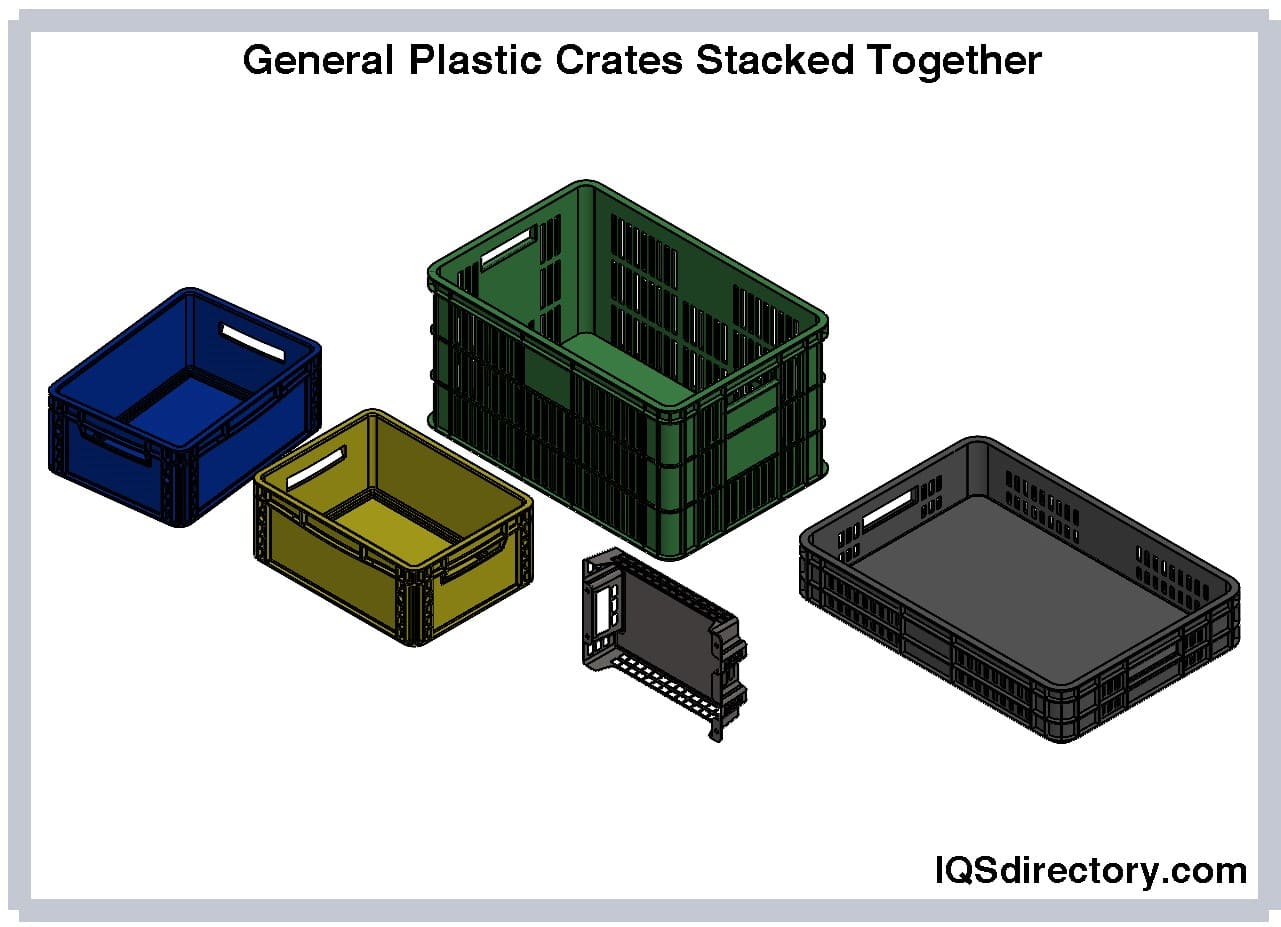

Types of Plastic Crates

Plastic crates are available in several specialized designs, each engineered to meet the unique requirements of specific applications. Understanding the different types can help you select the right crate for your operational needs, whether you’re looking for enhanced ventilation, capacity, security, or handling efficiency.

- Standard Plastic Crates: Ideal for general-purpose storage and transportation, standard crates are available in a variety of sizes, shapes, and colors. They are commonly made from polypropylene or polyethylene, offering a balance between strength and cost-effectiveness. Standard plastic crates are used for non-perishable goods, industrial parts, and retail merchandise. Looking for basic storage solutions? Explore how standard plastic crates can streamline your workflow and reduce handling time.

- Plastic Crates with Ventilation: Designed with open sides or perforated walls, ventilated plastic crates provide optimal airflow, making them perfect for storing and transporting fresh produce, dairy products, and other perishable items. Their stackable design and lightweight construction enhance distribution efficiency, reduce spoilage, and improve food safety compliance. Curious about the best crates for fruits and vegetables? Discover the advantages of ventilated plastic crates for agricultural supply chains.

- Closed Plastic Crates: Featuring solid walls and secure lids, closed plastic crates offer maximum protection against contamination, moisture, and tampering. They are frequently used for sensitive storage applications in the food, pharmaceutical, and fishing industries—such as the preservation of seafood, meats, and specialty goods. Closed crates are also favored for storing valuable or hazardous materials where security is paramount.

- Jumbo Plastic Crates: Engineered for extra-large storage and heavy-duty transport, jumbo plastic crates are capable of handling bulky products, industrial components, and high-volume shipments. Their reinforced construction ensures durability under extreme loads, and their spacious design accommodates oversized items that would not fit in standard containers. Need to move large or awkwardly shaped items? Learn how jumbo plastic crates can improve efficiency in bulk logistics.

Specialty Plastic Crates for Industry-Specific Needs

Beyond the standard categories, many manufacturers offer custom plastic crates tailored to unique industry requirements. For example, ESD-safe plastic crates are designed for the electronics industry to prevent static electricity damage to sensitive components. Pharmaceutical-grade plastic crates comply with strict hygiene and traceability standards for drug distribution. Temperature-controlled plastic crates featuring insulated walls and gel packs are used for cold chain logistics, ensuring temperature-sensitive products remain within specified ranges.

Looking for industry-specific solutions? Ask a crate specialist about custom designs, labeling, RFID integration, and color coding to support your operational goals.

Applications of Plastic Crates

- Dairy Industry: Milk crates and dairy transport containers are vital for the safe, hygienic distribution of milk bottles, cartons, and cans. Their rigid construction prevents spillage, contamination, and physical damage during transit, supporting efficient supply chains for dairy cooperatives and distributors.

- Agricultural Uses: Plastic crates are indispensable in farming, harvesting, and produce distribution, providing sanitary, reusable, and lightweight solutions for fruits, vegetables, and horticultural products. Their resistance to moisture and pests makes them preferable over wooden alternatives, enhancing food safety and shelf life.

- Fishing Industry: Fisheries and seafood processors rely on specialized plastic crates, fish tubs, and insulated ice boxes to prevent spoilage, maintain freshness, and facilitate rapid handling from catch to market.

- Fruits and Veggies: The perishable nature of fruits and vegetables demands careful handling and hygienic transport. Ventilated plastic crates reduce bruising, promote airflow, and prevent spoilage during long-distance shipping, helping growers and distributors maintain quality and reduce waste.

- Grocery Stores & Retail: Supermarkets, convenience stores, and grocery retailers use plastic crates for both backroom logistics and in-store handling. They streamline restocking, enable efficient shelving, and offer sturdy, reusable options for customer shopping baskets and temporary display units.

- Logistics and Warehousing: Plastic crates are widely adopted in warehousing, inventory management, and third-party logistics (3PL) operations, providing standardized, stackable units for automated material handling, order fulfillment, and reverse logistics.

- Industrial Manufacturing: Factories and assembly lines utilize plastic crates for sorting, storing, and transporting raw materials, work-in-progress items, and finished goods. Their compatibility with conveyors, forklifts, and AGVs (Automated Guided Vehicles) enhances process automation and workplace safety.

- Pharmaceutical and Medical: Hospitals, labs, and pharmaceutical companies require hygienic, traceable, and tamper-evident containers for medication, samples, and medical devices. Plastic crates designed for healthcare meet regulatory standards and simplify sterilization.

- Across all these sectors, plastic crates and containers play a pivotal role in optimizing supply chains, minimizing product damage, and supporting sustainable business practices.

Benefits of Plastic Crates

- Reusability and Cost Efficiency: Plastic crates are designed for repeated use, reducing the need for single-use packaging and lowering the total cost per trip over time. Their robust construction withstands frequent handling, drops, and stacking.

- Hygienic and Easy to Clean: Smooth surfaces and non-porous materials make plastic crates easy to wash, disinfect, and sanitize—critical for food, pharmaceutical, and medical applications where hygiene is paramount.

- Durability and Weather Resistance: Plastic crates resist moisture, chemicals, UV rays, and extreme temperatures. This resilience enables them to protect contents in harsh environments, including outdoor storage, refrigerated transport, and agricultural settings.

- Versatility in Size and Customization: Crates are available in diverse sizes, shapes, and colors, with options for custom branding, barcoding, and RFID tracking. This flexibility allows businesses to tailor solutions for specific workflows and branding requirements.

- Superior Load Capacity: Compared to cardboard or wooden alternatives, plastic crates offer enhanced load-bearing strength and impact resistance, making them suitable for heavy, bulky, or fragile items.

- Stackability and Space Efficiency: Ergonomically designed for secure stacking and nesting, plastic crates optimize storage density and reduce shipping volumes, resulting in lower freight costs and improved warehouse utilization.

- Environmental Sustainability: Most plastic crates are recyclable, and many manufacturers offer take-back or recycling programs to promote a circular economy. Reusable crates significantly reduce packaging waste, supporting corporate sustainability initiatives.

How to Choose the Best Plastic Crate for Your Needs

With the vast array of options available, selecting the right plastic crate requires careful consideration of your unique operational requirements, product characteristics, and industry standards. Here are key decision factors to guide your purchase:

- Intended Application: Determine whether your crates will be used for food handling, industrial parts, pharmaceuticals, retail, or agriculture. Each application may require specific features such as ventilation, insulation, or tamper-evident seals.

- Load Capacity & Dimensions: Assess the weight, volume, and size of items you plan to store or transport. Choose crates that can safely accommodate your heaviest loads without compromising structural integrity.

- Stacking and Nesting Requirements: Evaluate your need for collapsible, stackable, or nestable designs based on storage space, return logistics, and workflow efficiency.

- Material Selection: Consider whether polypropylene, high-density polyethylene, or specialty plastics best meet your durability, chemical resistance, and environmental exposure requirements.

- Hygiene & Cleaning: For food and healthcare uses, prioritize crates with smooth surfaces, minimal seams, and compatibility with industrial washing systems.

- Custom Features: Explore options for custom colors, logos, RFID tags, barcodes, or tamper-evident lids to support branding, traceability, and regulatory compliance.

- Sustainability Goals: Ask about recycled content and end-of-life recycling programs to align with your company’s environmental objectives.

Have specific requirements? Contact a plastic crate specialist to discuss custom solutions, sample requests, or industry certifications.

Frequently Asked Questions About Plastic Crates

- What are the main advantages of plastic crates versus wooden or cardboard alternatives?

- How do I choose between ventilated and closed plastic crates for my products?

- Are plastic crates compliant with food safety and hygiene standards?

- Can I order custom-sized or branded plastic crates for my business?

- What is the expected lifespan of a reusable plastic crate?

- How can I recycle or dispose of plastic crates responsibly?

- What stacking orientation is best for my warehouse or distribution center?

Choosing the Proper Plastic Crate Manufacturer

To ensure you achieve the best results when purchasing plastic crates, it is crucial to select a reputable and experienced plastic crate manufacturer. Begin your search by comparing several companies using our directory of plastic crate manufacturers. Each profile highlights the manufacturer’s areas of expertise, capabilities, and production methods—helping you identify specialists in injection molding, custom design, or food-grade plastics.

Visit each plastic crate supplier’s website using our proprietary website previewer for a quick overview of their product catalog, certifications, and customer reviews. Use our simple RFQ form to contact multiple manufacturers simultaneously, requesting quotes and detailed product information tailored to your project specifications.

When evaluating potential partners, consider factors such as:

- Production capacity and lead times

- Quality assurance processes and certifications (ISO, FDA, HACCP, etc.)

- Availability of custom solutions and value-added services (printing, labeling, recycling)

- Experience in your industry or application area

- Customer service and technical support resources

- Pricing, minimum order quantities, and shipping logistics

Ready to find the right plastic crate manufacturer? Browse our directory or request a quote today for expert guidance and competitive pricing.

Conclusion: Unlocking Operational Excellence with Plastic Crates

Whether you operate in agriculture, food processing, manufacturing, logistics, or retail, high-quality plastic crates can transform your storage, handling, and distribution processes. Their durability, reusability, and versatility offer long-term cost savings, improved product protection, and support for sustainable business practices. By choosing the right type of plastic crate—tailored to your application, workflow, and industry regulations—you can optimize operational efficiency, reduce waste, and enhance your company’s competitive edge.

Still have questions or need a custom solution? Contact our team for personalized advice, product samples, or a no-obligation quote. Explore our full range of plastic crates and discover how the right storage and transport solution can drive your business forward.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services