Plastic tubs are storage units made of several crude oil or natural gas polymers. The raw petroleum ingredients are converted using various chemical procedures into thermoplastics, designed to be molded, structured, and molded into resilient, long-lasting, and robust transport and storage containers. Plastic containers were initially used at the start of the first industrial revolution and have since become a crucial component of manufacturing and transportation activities. Read More…

As a leader in the plastic container & plastic food container industry, Rahway Steel Drum Company supplies plastic storage containers, plastic shipping containers & more, to be used for regulated & non-regulated liquid & solid packaging. Choose from our many sizes from 1 quart to 330 gallons. For 60 years we have been a plastic container distributor of lightweight, space saving, bulk containers.

Jakacki Bag & Barrel, family owned and operated, is a plastic container manufacturer. Their products include pails, pallets, gaylords, drums and so much more.

Container Distributors offers a solution for all of your plastic container needs, including all sizes of new and reconditioned plastic containers, as well as steel and fibre drums. We also carry a wide range of cubic yard boxes and IBC/totes.

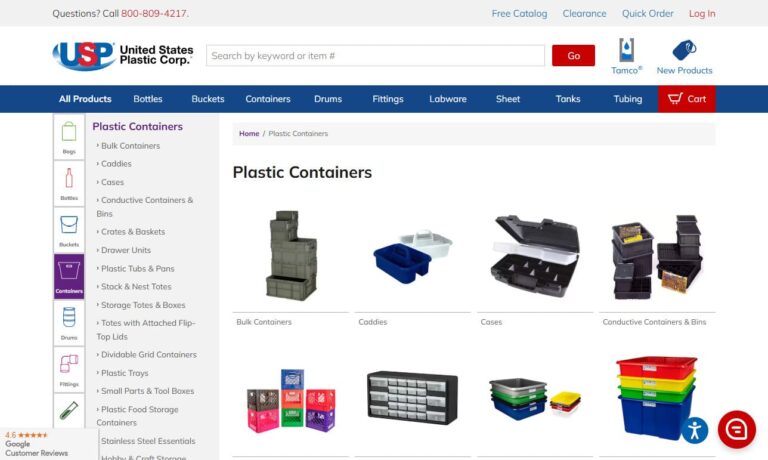

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

At BayTec Service, we specialize in providing high-quality plastic containers designed to meet the diverse needs of industries ranging from chemical processing to food storage and industrial manufacturing. We take pride in offering an extensive selection of durable, versatile containers that deliver long-term performance in demanding environments.

For the past 30 years, Western Industries has been manufacturing plastic containers for a variety of industries, and fulfilling the needs for businesses large and small. At our 350,000 square-foot manufacturing campus, we have the technology and the expertise to manufacture plastic containers of all shapes and sizes, defect-free.

More Plastic Tub Manufacturers

Numerous plastic containers, ranging from soda bottles to shipping containers several feet high and broad, may be made using various production techniques. The vast majority of plastic containers are created using an injection molding process where a plastic resin is forced into a die of the object being created. Other processes include rotational molding, compression molding, and extrusion blow molding; additional methods must be considered depending on the purpose of the end product.

Whether you are looking for plastic storage solutions for industrial, commercial, or household applications, understanding the different manufacturing processes and types of plastic containers can help you make an informed decision. In this comprehensive guide, we’ll cover the most common types of plastic containers and tubs, their construction, molding processes, applications, benefits, and key considerations for choosing the best plastic tub supplier for your needs.

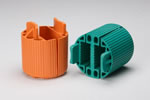

Types of Plastic Containers

Plastic containers come in a vast range of shapes, sizes, and specifications, each designed to meet unique storage, packaging, transport, and organizational needs. Common types include:

- Plastic Folding Boxes: In the packaging sector, plastic folding boxes are a developing trend. They are a tasteful and economical way to present goods. These transparent boxes are often made from polyethylene terephthalate (PET) or polyvinyl chloride (PVC), providing clarity and rigidity for retail displays, bakery packaging, gift wrapping, and more. Their foldable design makes them easy to store and ship flat, reducing logistics costs.

- Plastic Barrels: Plastic barrels are generally produced using high-density polyethylene (HDPE) material since it lends to their strength and durability. They are ideal for many industrial tasks, such as packing, storing, transporting, and disposing of fluids and other materials. These industrial plastic drums are widely used in the chemical, food processing, pharmaceutical, and agricultural sectors for bulk storage of liquids, grains, powders, and hazardous substances. Their resistance to corrosion and impact makes them suitable for long-term outdoor storage.

- Plastic Gas Cans: Designed to safely contain gas, plastic gas cans are constructed from various thermoplastic materials. They offer a secure and practical way to transport and store gas. For consumer convenience, they typically come in multiple sizes, from one gallon to more than 10 gallons. Plastic fuel containers are required to meet strict safety standards regarding permeability, flame resistance, and child safety. Commonly used in automotive, landscaping, and emergency preparedness applications, these cans are lightweight, portable, and durable.

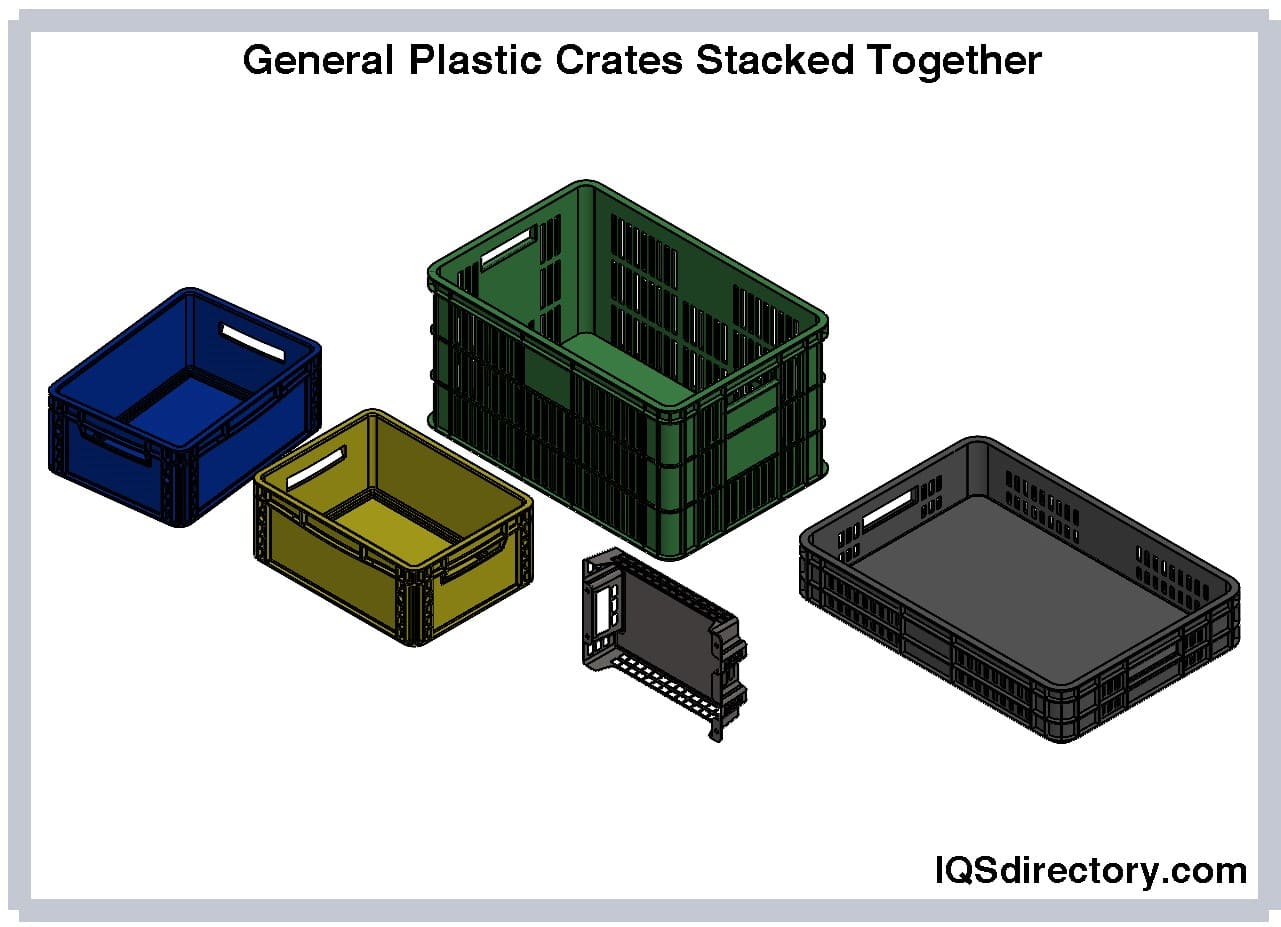

- Plastic Shipping Crates: Plastic shipping boxes are incredibly robust, strong, and sturdy crates that withstand stress during long-distance transit and are built for years of continuous usage. These reusable plastic shipping containers are available in nestable, stackable, and collapsible designs. Applications include distribution centers, e-commerce fulfillment, food service, and electronics logistics, where impact resistance and ease of cleaning are important.

What Are the Most Popular Plastic Container Materials?

When choosing a plastic container, it’s essential to understand the different materials available. The most common plastics used in container production include:

- Polyethylene (PE): Used for bottles, tubs, and flexible containers due to its flexibility, impact resistance, and moisture barrier properties.

- Polypropylene (PP): Suitable for food storage, microwavable containers, and medical uses because of its heat resistance and chemical stability.

- Polyethylene Terephthalate (PET): Known for clarity and strength, ideal for water bottles, salad containers, and clamshell packaging.

- Polyvinyl Chloride (PVC): Used in specialty containers where clarity and rigidity are crucial, though less common for food use.

- Polystyrene (PS): Lightweight and rigid, used for disposable plastic containers and trays.

- High-Density Polyethylene (HDPE): Commonly used for industrial drums, barrels, and heavy-duty storage bins.

Looking for a specific type of plastic container for your project?

Try searching for terms like custom plastic tubs, food-grade plastic containers, or industrial storage bins to narrow down your options.

Construction of Plastic Tubs

- Although tubs may be created using materials such as aluminum, molded pulp, or paperboard, plastic tubs are created using various plastic materials, such as PET polyester, polystyrene, or polypropylene.

- Certain plastic tubs include unique microwave characteristics, like susceptors, which are used to absorb electromagnetic energy and convert it to heat.

- Before the lid is put on, users can add a heat-sealed lidding sheet to the tub. Some tubs feature a security strip or tamper-evident band to denote unintentional or unwanted openings.

- There are many different kinds of latches and methods for attaching lids.

- A tub's body and cover can be printed with labels or have labels affixed to them.

Plastic Tub Lid Options and Security Features

Depending on your application, you may require plastic tubs with:

- Tamper-evident lids for food service, pharmaceuticals, or retail packaging.

- Snap-on, screw-top, or hinged lids for ease of access and resealability.

- Custom printed labels and in-mold labeling for branding and product identification.

How Does Plastic Tub Construction Impact Performance?

The choice of resin, wall thickness, and lid design all affect a tub’s durability, chemical resistance, and suitability for specific storage conditions. For example, food storage containers must comply with FDA food safety standards and offer airtight seals, while industrial tubs may require UV stabilization for outdoor use or anti-static properties for electronics packaging.

Manufacturing and Molding Procedure of a Plastic Tub

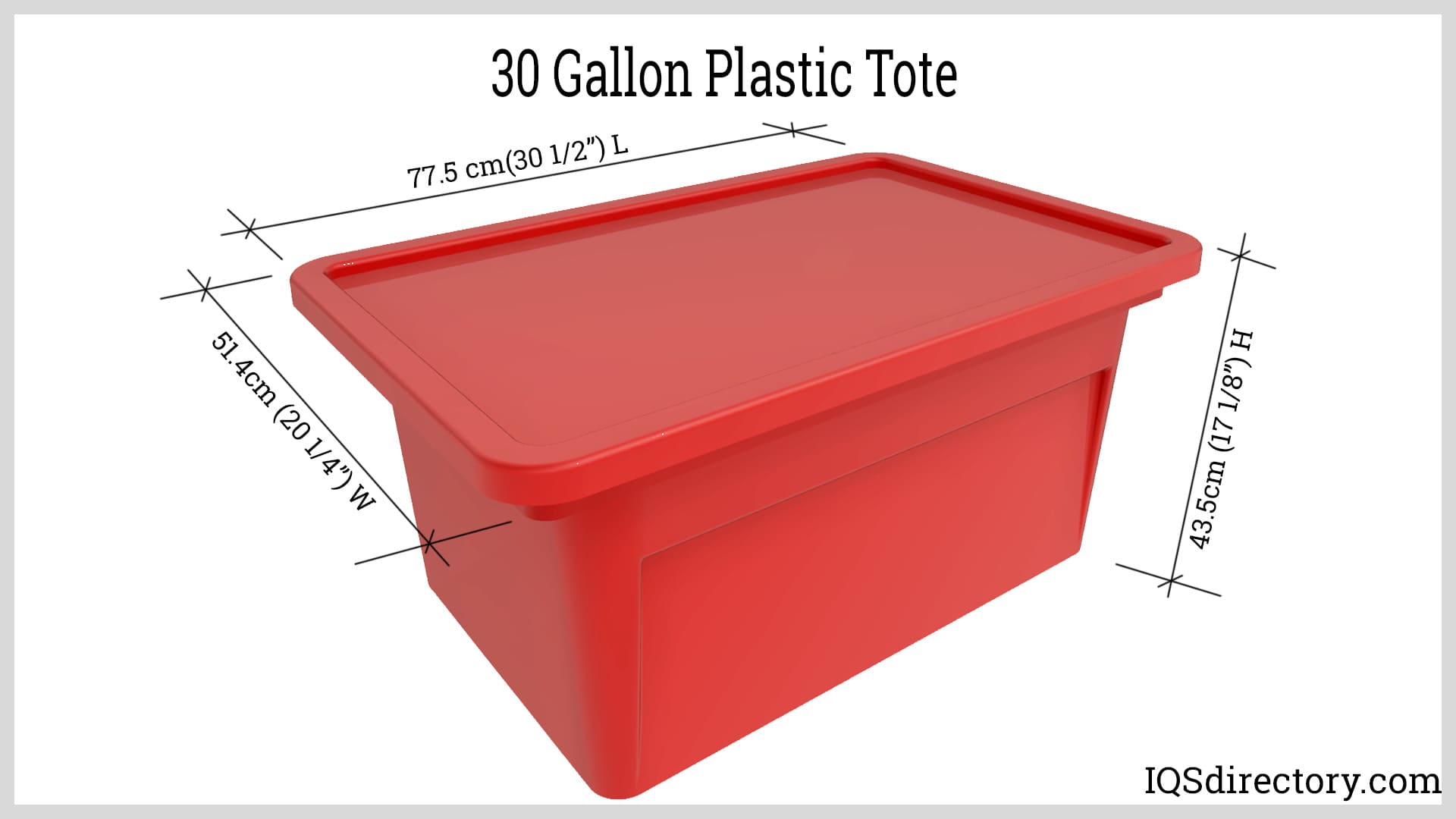

- Blow-molded high-density polyethylene (HDPE) or polyethylene terephthalate (PET) is used to create each container.

- They may be created in various forms, colors, and sizes. For ease of transportation, plastic tubs are typically made with sealing lids or lids and tops that interlock.

- All blow-molded plastics go through a similar manufacturing process.

- Every blow mold machine starts with a stock- a collection of unprocessed plastic resin.

- A hopper that sends the stock into a conveyance channel is filled with the product.

- The stock is pushed toward the mold by a sizable screw that spins in the conveyance channel.

- Heating elements in the conveyance channel heat the stock as it moves toward the mold, and this, along with the pressure created by the spinning screw, causes the plastic to liquefy.

- The differences in the molding process start to emerge at this phase. Although they all function using the same principle, molds differ in how they are built.

- In the process of blow-molding plastic tubs, the liquid plastic enters a sizable cavity and assumes the shape of the mold.

- The plastic is then pushed into the cavity accompanied by compressed air, which makes the material become hollow and take on its final tub-like form.

- After cooling and becoming rigid, the molten plastic is removed from the mold.

Alternative Plastic Tub Manufacturing Methods

Besides blow molding, other plastic tub manufacturing techniques include:

- Injection molding: Ideal for high-volume production of small to medium-sized tubs with precise dimensions and smooth finishes. Commonly used for food storage containers, laboratory sample vials, and cosmetic jars.

- Rotational molding: Used for large, hollow tubs and tanks with uniform wall thickness. This method is popular for manufacturing bulk storage bins, water tanks, and playground equipment.

- Thermoforming: Involves heating a plastic sheet and forming it over a mold. Suitable for lightweight disposable tubs, trays, and packaging inserts.

- Compression molding: Often used for specialty tubs requiring reinforced strength or heat resistance.

Wondering which molding process is best for your application?

Contact a plastic tub supplier or manufacturer to discuss your specific requirements, such as volume, size, wall thickness, and intended use. They can recommend the most cost-effective and durable manufacturing method.

Applications of Plastic Tubs

- Order pickers on a warehouse floor may place orders in plastic bins, food distributors ship their products in plastic tubs, and medical laboratories freeze materials in plastic containers.

- Even though there are various methods available for workers who use tools, one of the most popular solutions for small businesses is to arrange their instruments into different plastic containers so that they may be kept separate while still being accessible.

- Homeowners in many nations store their off-season items and clothing in stackable plastic containers.

- Although we live increasingly digital, your home or business will still accumulate paperwork. An appropriately-sized plastic container that allows you to organize and store these papers on the off chance they are needed may provide great peace of mind.

Common Use Cases for Plastic Tubs and Containers

- Food storage and packaging: Ice cream tubs, deli containers, bakery packaging, takeout containers, and ingredient bins.

- Industrial and warehouse storage: Bulk parts bins, sorting trays, and component organizers for manufacturing and logistics.

- Laboratory and medical applications: Sample collection tubs, biohazard waste containers, and sterilizable storage.

- Home organization: Toy storage, seasonal clothing bins, document organizers, and craft supply containers.

- Commercial and retail display: Clear plastic tubs for merchandising, product sampling, and promotional packaging.

- Outdoor and garden use: Planter tubs, water reservoirs, and feed bins that resist weather and UV exposure.

- Hazardous materials containment: Certified containers for chemicals, paints, and hazardous waste storage.

Questions to Ask When Selecting Plastic Tubs for Your Application

- Does the tub need to be food-safe or meet FDA regulations?

- Will the container be exposed to outdoor elements or extreme temperatures?

- Is chemical resistance or static dissipation required?

- Does the application need stackability or nesting features for storage efficiency?

- Is custom branding or color matching important for your project?

- Will you need bulk quantities or custom sizes manufactured?

Benefits of Plastic Tubs

- When it comes to material formability, plastics are fantastic. As a result, plastic tubs can be created using various methods.

- Unlike metal containers, plastic ones are not similarly impacted by environmental factors. Rust forms on metals and weakens the structural integrity of any container made of these materials. Plastics do not rust.

- Plastics are between 0.8 and 1.5 times denser than water. Glass and ceramics have densities of around 2 to 3 times steel, with a thickness of about 7.8.

- Different sorts of chemicals can be converted into plastic containers using various techniques. Every kind of plastic has built-in mechanical qualities.

- Plastic tubs provide exceptional impact and tear resistance.

- They possess excellent surface qualities and aesthetics. Containers made of plastic can have nearly any appearance.

- Plastic containers may be recycled, just like Glass and metals can. Historically, melting and heating have been used to recycle plastics.

- Compared to metal and glass containers, plastic containers are simpler to make and use less energy to create, which results in lower costs.

Additional Advantages of Using Plastic Tubs and Containers

- Lightweight yet strong: Reduces shipping and handling costs while maintaining durability.

- Moisture and chemical resistance: Suitable for food, pharmaceuticals, and chemicals.

- Wide variety of sizes and shapes: From mini sample vials to large bulk storage tubs, there’s a container for every use case.

- Customizable: Choose from color options, printing, labeling, and special features like UV resistance or anti-static properties.

- Stackable and nestable designs: Save valuable space in warehouses, retail backrooms, and homes.

- Reusable and recyclable: Many plastic tubs can be reused for years and eventually recycled, supporting sustainability goals.

- Cost-effective: Lower production, storage, and shipping costs compared to alternatives like glass or metal.

How Do Plastic Tubs Compare to Other Storage Solutions?

When evaluating storage and packaging solutions, plastic tubs often outperform cardboard, glass, or metal containers in terms of:

- Longevity: Plastic resists denting, rust, and breakage.

- Weight: Easier to handle and transport.

- Versatility: Suitable for wet or dry, food or industrial, indoor or outdoor use.

- Safety: No sharp edges, shatterproof, and in many cases, food-grade and BPA-free.

Choosing the Right Plastic Tub Supplier

To ensure you have the most productive outcome when purchasing plastic tubs from a plastic tub supplier, it is important to compare several companies using our directory of plastic tub suppliers. Each plastic tub supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each plastic tub business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic tub companies with the same form.

Key Factors to Consider When Selecting a Plastic Tub Supplier

- Product range: Do they offer the specific size, shape, and material you need?

- Customization options: Can they provide custom colors, logos, or special features such as tamper-evident lids?

- Quality assurance: Are their products certified for food safety, industrial use, or hazardous material handling?

- Minimum order quantities and lead times: Can they accommodate your project’s requirements?

- Pricing and value: Are their prices competitive for bulk orders or custom runs?

- Customer service: Do they provide technical support, samples, and fast response to inquiries?

- Sustainability: Do they offer recyclable products or use recycled materials?

Ready to Request a Quote or Sample?

Use our directory to compare plastic tub suppliers, request product samples, and get pricing for your next project. Looking for custom plastic packaging, bulk storage containers, or specialty industrial bins? Reach out today to discuss your requirements and get expert guidance.

Frequently Asked Questions about Plastic Tubs and Containers

- What are the best plastic tubs for food storage? Look for containers made from food-grade polypropylene (PP) or PET, with airtight, tamper-evident lids and FDA-compliant materials.

- Are plastic tubs recyclable? Most tubs made from HDPE, PP, or PET are recyclable through curbside programs or specialized recycling centers. Check local guidelines for accepted resin codes.

- Can I order custom sizes or colors? Many suppliers offer custom molding and color matching for orders meeting minimum quantities. Ask about custom branding and labeling, too.

- What is the typical lead time for bulk orders? Lead times vary by manufacturer, order size, and customization requirements, but standard items are often available within 2-6 weeks.

- How do I ensure my plastic tubs meet regulatory requirements? Request documentation on FDA, USDA, or NSF certifications as necessary for your industry and intended use.

Still have questions about choosing the right plastic tubs or containers?

Explore our resource center or contact us for expert advice, technical data sheets, and personalized recommendations to help you find the perfect plastic container solution for your unique needs.

Conclusion: Find the Best Plastic Tub for Your Application

Plastic tubs and containers are an essential part of modern storage, packaging, and logistics for industries ranging from food processing to pharmaceuticals, retail, manufacturing, and home organization. With a wide selection of materials, sizes, features, and customization options available, choosing the right plastic container ensures product safety, operational efficiency, and cost savings.

By understanding the types of plastic tubs, manufacturing methods, application-specific requirements, and supplier capabilities, you can make an informed decision that meets your business or personal needs. Ready to get started? Browse our supplier directory, request quotes, and access expert guidance on all aspects of plastic container solutions today!

55 Gallon Drums

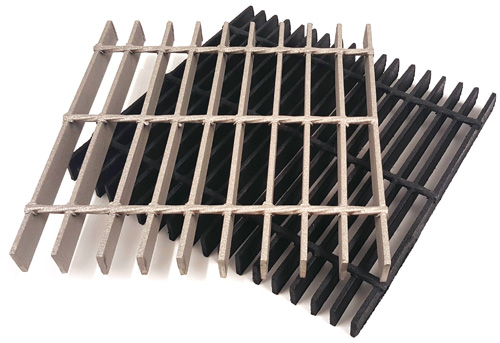

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services